Buying a 5-Axis Machining Center? 5 Tooling Variables to Consider

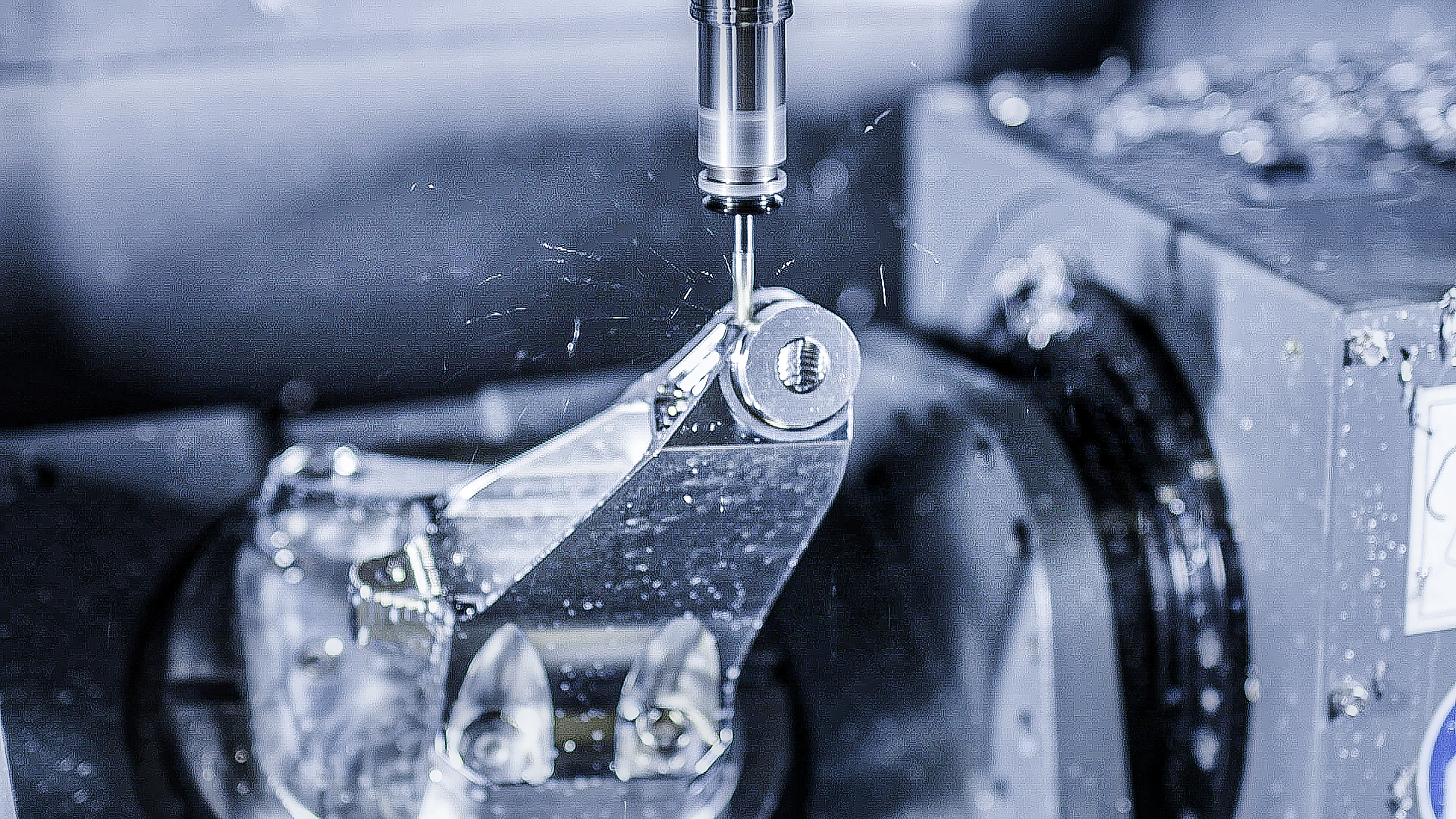

Even the most carefully maintained machining centers eventually become obsolete. When it’s time to replace your older machine, look for one that gives you the maximum dollar value for your investment. 5-axis machining centers are versatile, efficient and flexible, and one can do the work of two or three 3-axis machines.

With that new machine comes an opportunity to upgrade your tooling, as newer machining centers can handle more advanced tooling options. Consider these tooling variables when purchasing a new 5-axis machine.

5 things to consider when tooling up a New 5-AXIS machine

-

Update your tooling assortment with improved insert grades to yield better tool life and results than older tools. Investing in the latest grades and materials will help you achieve greater economies and efficiencies.

-

Reduce your tool inventory with an ISO certified quick-change holding system. Minimize the number of different holders in your inventory with a solution like Coromant Capto. This one holding system can be used for milling, drilling and turning, and with over 5,500 integrated Coromant Capto cutting heads and adapters, you will never need another system.

-

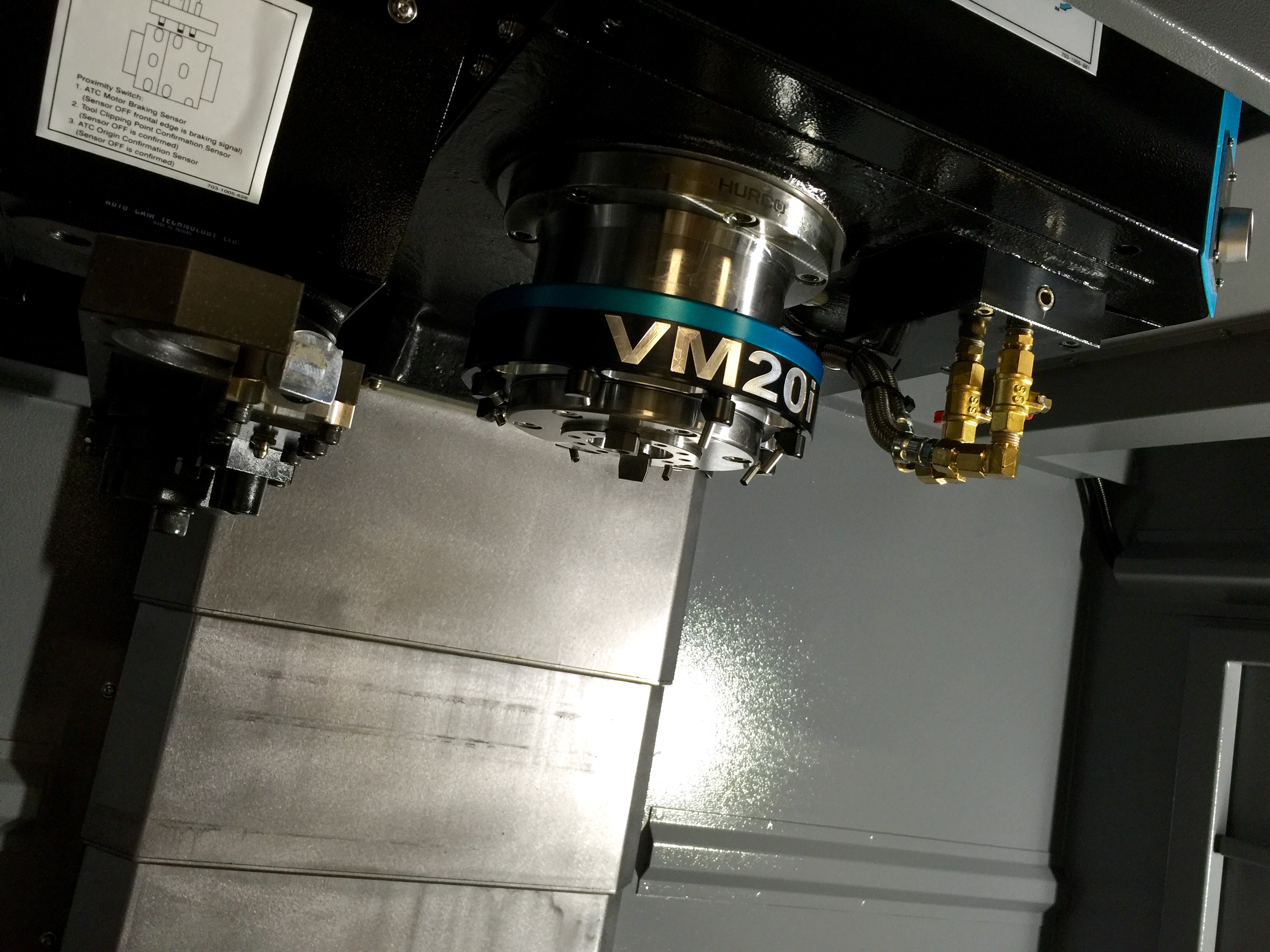

Optimize chip control through high-pressure coolant (HPC). In operations where coolant is needed, HPC yields better chip formation and evacuation. With a short-chipping result, you get better efficiency from the action of the hydraulic wedge formed by the directed pressure of the coolant and more out of your inserts as the stress on the insert is reduced. Longer tool life plus better chip control equals a more efficient and profitable process. Hurco VMX machining centers and TMX turning centers easily accommodate HPC.

-

Budget tooling into your capital expense to get all of the tax advantages from your new investment. Talk to your financial team and your machine tool dealer/builder for a tooling certificate and more information.

-

Get the proper education to get the most out of your new machines and new tooling. Seek out programs available in schools, use online resources such as Hurco Connect to train your production people so that everyone gets the maximum value.

You'll find more helpful resources, such as training videos and webinars, at Hurco Connect.

Don't forget to subscribe to the CNC Machining Blog! You'll receive an email notification whenever a new post is published.