Should You Buy New or Used CNC Machine? What's ROI of Training?

Should you buy a new or used CNC machine for your shop? Does taking the time to train your machinists really pay off?

Hi, I'm Maggie Smith, and I'm hijacking Mike Cope's blog this week. The questions this blog post addresses arose after Mike visited a machine shop in New Jersey. As a product technical specialist, Mike visits shops throughout the US. When Mike returned from his New Jersey trip, he told us about his experience, and I thought it would be good information to share with his readers.

CNC MACHINIST TRAINING: IS TAKING THE TIME REALLY WORTH IT?Mike was in New Jersey conducting an on-site training session because he is a veteran applications engineer, which means he was here at Hurco during the days of UltiMax — the Hurco control operating system prior to WinMax®. This particular customer had an older Hurco with UltiMax and decided they might be able to improve setup time with some training.

Smart move!

The part that was taking them three days complete now takes just four hours! Mike helped them adjust speeds and feeds so they didn't burn up tools and scrap parts. Some of the lengthy three-day part time was due to the fact that they could only complete part of the operation on the CNC mill and felt they needed to finish it on a manual machine. This was due to a lack of training on the CNC mill. With training costs of $5,000, plus travel expenses, it doesn't take a mathematician to see that the investment in training paid off immediately for this customer.

By training the crew on the control and its capabilities, Mike helped them figure out a better process that saved tons of time. For instance, on the one side of the part, they had to chamfer all of the holes. The other side had to have two grooves in the holes dimensioned from top side down. They were doing those grooves with a mechanical tool, and sometimes the tool would fail.

Mike helped them change the type of tool they used for the grooves, which gave them more control over the grooves. Now, they can get everything done in one setup except chamfering the holes, which they can do offline while the next part is running on the CNC machine.

NEW VS USED CNC MACHINES: HOW OLD IS TOO OLD?

Obviously, all of us at Hurco want people to buy new machines. However, we are proud that the old Hurcos stand the test of time. To borrow an old school jingle from the Timex watch commercial, "They take a licking but keep on ticking!"

(Michigan customer with their first Hurco, affectionately named "old blue")

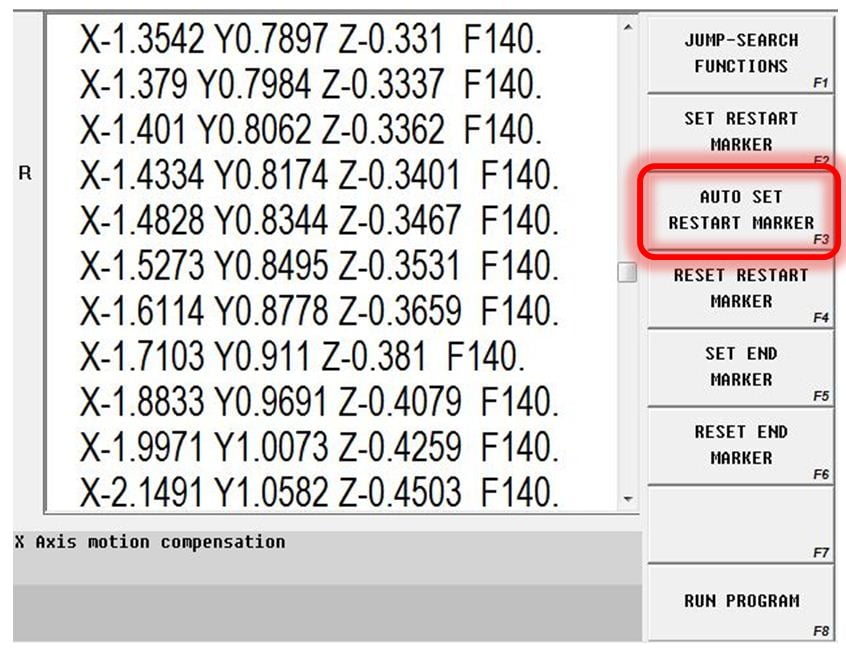

We love it when people send us pictures of "old blue" still making chips years later. However, when Mike explained how he had to train the NJ shop to program the part using the old UltiMax control, we discussed what control features they were missing, and more importantly, how much time they would save by investing in a new Hurco with the latest WinMax® control. The specific WinMax® features Mike said would have made the biggest impact on this specific part are Tool Change Optimization and UltiMotion.

Tool Change Optimization (TCO): the control prioritizes the tool changes by operation, such as roughing, finishing and holes operations, which makes it more efficient. Below is an example from a test part.

| TCO | Tool Changes | Estimated Run Time |

| Off | 75 | 12:03 |

| On | 3 | 4:01 |

With TCO turned off, each hole is handled individually, which means the machining center drills, drills, and then taps one hole; center drills, drills and taps the next hole, and so on until all 25 holes are complete. Without TCO, this puts pressure on the programmer to program around all of these tool changes manually.

CONCLUSION

Training is an investment. Your business is worth it. Make sure you keep your crew trained, especially as new people are hired. Second, consider what you're missing when you buy a used CNC machine. It's easy to get in the rut of doing things the same way, but technology is continually evolving and improving. Thankfully, our new control allows customers to upgrade to the latest software, so you don't have to miss out on improvements.

Click here to download a free 90-day WinMax® trail for your desktop so you can test things out for yourself.

Don't forget to subscribe to the CNC Machining Blog! You'll receive an email notification whenever a new post is published.

You'll find more helpful resources, such as training videos and webinars, at Hurco Connect.