Modern Machine Shop visits Hurco to check out our N95 Mask Project

Peter Zelinski from Modern Machine Shop magazine stopped by Hurco last week to check out the N95 mask project we started due to the COVID-19 pandemic.

Greg Volovic, our President and Chief Operating Officer, challenged the engineering team to adapt one of our machines to be capable of making N95 masks for virus protection. They had four weeks to make it happen.

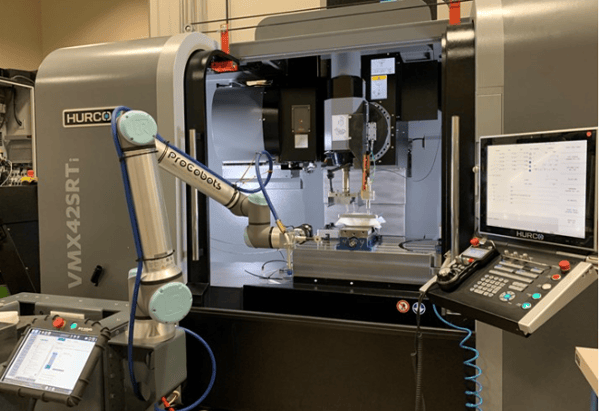

One of the first challenges our engineers faced is a symptom of offshoring. When the manufacturing of a product is "off-shored" the knowledge of "how it's made" gets offshored, too. They realized the fastest way to figure it out how an N95 mask was made was to disassemble an existing mask. Next, they identified the best process and what machine and peripheral equipment they would need. The masks are made on the Hurco 5-Axis CNC machine that has a swivel head and rotary torque table (the VMX42SRTi), the ProCoBots Automation System featuring a robot from Universal Robots that automated the forming, welding, and cutting processes. An excerpt from the Modern Machine Shop article follows:

"Greg Volovic, president of machine tool supplier Hurco, gave a challenge to engineering staff members at the company’s Indianapolis headquarters: Within four weeks, adapt a machine tool into a system for making N95 masks for virus protection. It didn't have to be an optimized system — refinement could come later — but he asked for a system that could make the mask (sans straps) complete. The challenge was met, so Hurco is now theoretically self-sufficient for N95 mask production. Capacity allowing, the company can make masks for its customers, employees and distributors."

Click this link to watch the video and read the

full article on Modern Machine Shop's website.