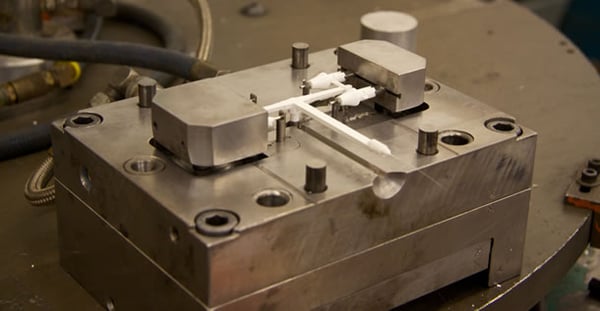

Known for its efficient design that yields a small foot print yet large work envelope, the VM20i is highly versatile and adept at both prototype and small volume jobs as well as the occasional repetitive job. In PlastiCert’s case, the VM20i will be integral to its mold build function. It will machine both graphite and steel.

Minnesota Injection Mold Company Selects Hurco VMC due to Versatility

Plasticert is on the move. I got an email from our distributor in Minnesota, Stone Machinery, who shared the news release Plasticert Injection Molding Solutions sent them about their company's newest addition.

Plasticert recently took delivery of a new Hurco VM20i CNC machining center, which is part of the 37-year-old company's $1 million capital improvement plan and facility expansion.

“With the new features this unit has, combined with the larger bed size we chose, we’ll be much more productive. The increased capability will allow for even more complex mold designs than we have engineered to date”, commented PlastiCert mold designer and Tooling Manager Dean Rupprecht.

Additionally, the Hurco VM20i is equipped with UltiMotion (invented by Hurco and only available on Hurco CNC machines) and the integrated Hurco control that includes both conversational and NC programming capabilities as well as robust technical specifications, such as 10,000 block look-ahead, 4GB RAM, and a 128GB Solid State Hard Drive, all standard instead of an option that adds to the cost of the machine.