Vincennes Students Get Ahead of the Skills Gap with the Hurco Control

This past Wednesday team members from Hurco went down to Vincennes, Indiana, to visit with students from the Advanced CNC Machining and Programming at Vincennes University to shoot a new video discussing their time in the program and how the Hurco Control has helped them bridge the gap that many companies need with skilled workers (the video will be released later).

Students in this summer course are taught over a 14-week time period. Throughout the course they learn to program, machine, and inspect complex 2, 3, 4, and 5-axis parts. The class is designed to make use of high-speed machining, for companies specializing in die making, mold making, aerospace, medical, and other industries.

During our visit, we were able to talk to a few students and get their thoughts on the Hurco Control as well as see some of the parts they made during their time in the course.

.jpg?width=711&name=My%20Post%20(1).jpg)

Avery Byers

"Hurco is very easy to get a handle of versus most of their competitors, the conversational control is the easiest in my opinion."

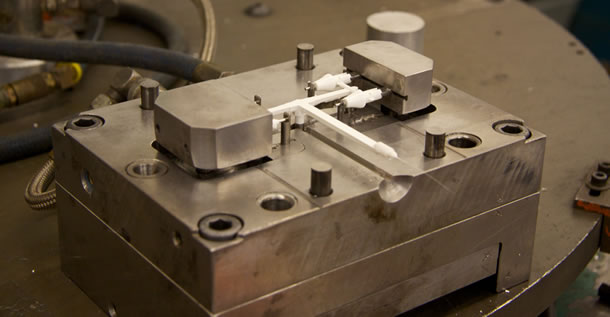

Demo Part, made on the Hurco VM10i with the 4th axis. Total run time was around 1:35:00 with Avery's setup and ops included. This part was to help the students get introduced to the 4th axis control and programming toolpaths.

Dakota Hill

"I like the windows based control from Hurco, it doesn't have a ton of buttons, it's compact and clean versus other machines whose controls are cluttered."

3d Super Smash Bros themed clock with raised Roman numerals, made from aluminum with a 7:30:00 cycle time on the Hurco VM20i.

The students in this course have about 4 weeks left of school. From here, they plan on going out into the workforce confident knowing that they have the required skills that companies are looking for in today's workforce. They give credit to their great instructors at Vincennes University and to Hurco for making a machine and control that is built for any generation.