Reduce Programming Time with Enhanced Corner Geometry: CNC Control

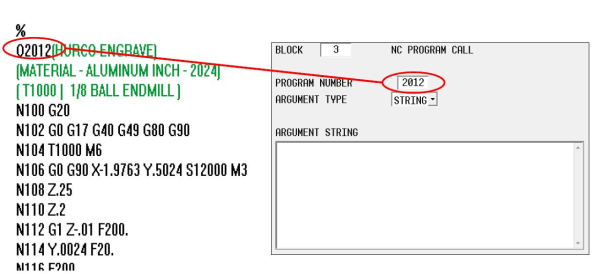

In the past, when using the Hurco control to program rectangular shaped geometries in which the four corners weren’t square or didn’t all have the same size radii, the feature needed to be programmed using a "MILLING LINES & ARCS" data block. However, thanks to the advancement of WinMax® mill software, this obstacle is now a thing of the past.

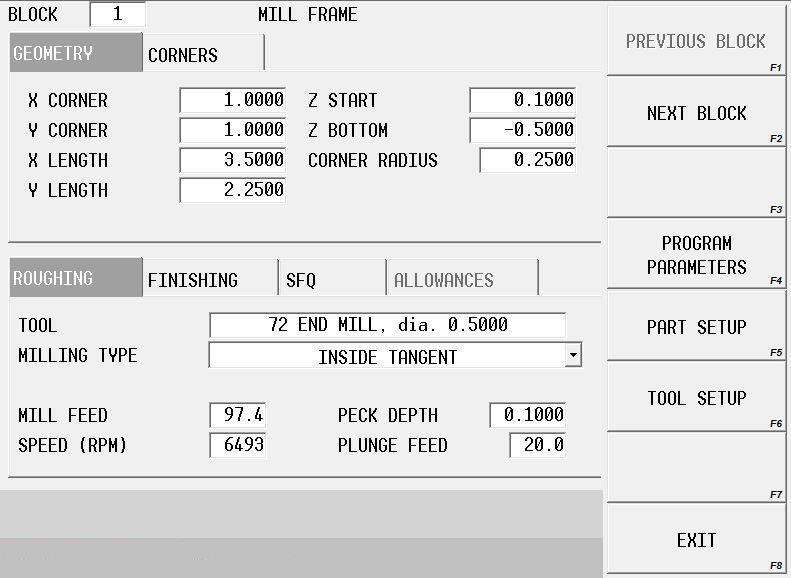

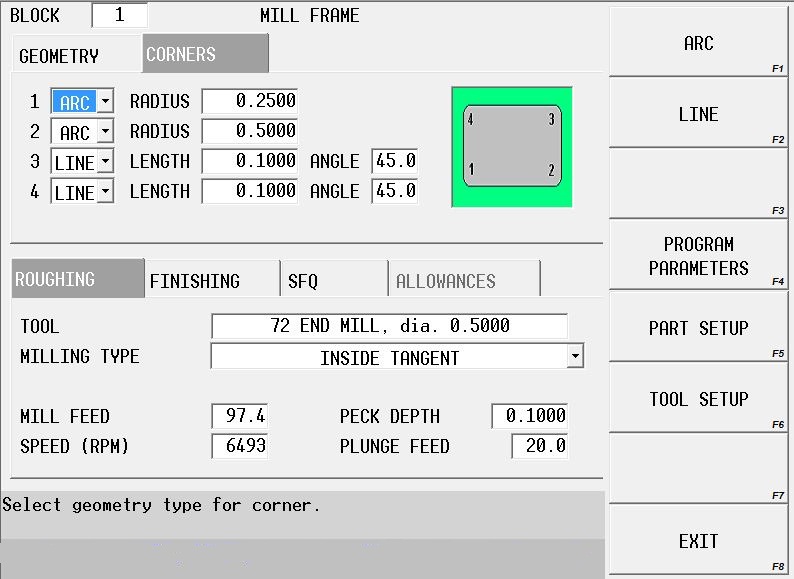

Today, when programming a "MILL FRAME" data block with variations in one or more of the four corners, the task is quite simple. Each corner of the frame has been assigned an identifying number and given individual controls.

The programmer will simply select the “CORNERS” tab within the data block and enter the necessary data for each of the four corners independently. By use of the supplied pull-down menus, each corner can be programmed with either a simple corner radius or a chamfer or line with a specified length and angle.

.jpg?width=600&height=438&name=ehnanced-frame-corners-(1).jpg)

.jpg?width=600&height=437&name=ehnanced-frame-corners-(2).jpg)

You'll find more helpful resources, such as training videos and webinars, at Hurco Connect.

Don't forget to subscribe to the CNC Machining Blog! You'll receive an email notification whenever a new post is published.