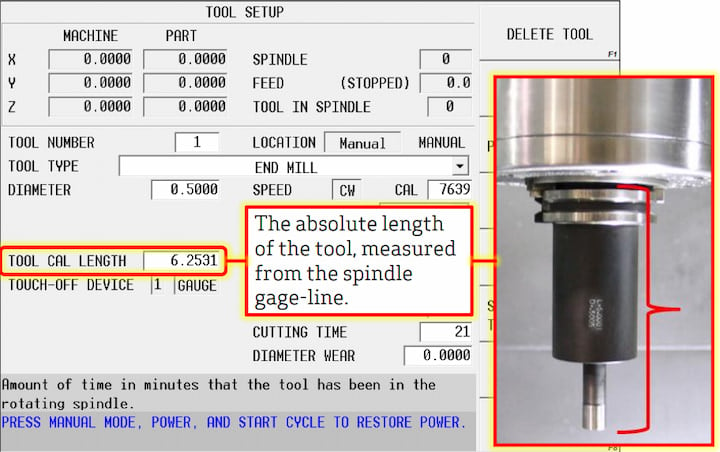

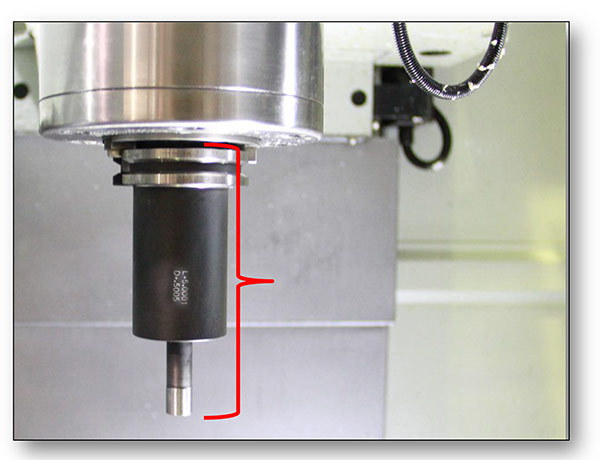

Absolute Tool Length: the industry standard

As many of you are already aware, the Absolute Tool Length method of tool calibration has become the industry standard for measuring and recording the length of individual cutting tools on milling machines. This method of tool measurement not only produces numerical values that make sense to the operator, and can easily be verified with a pocket scale, but will also allow for tool lengths to be set offline using a presetter - and then the data can simply be entered into the tool setup for that particular tool…helping to reduce setup time at the machine.

As many of you are already aware, the Absolute Tool Length method of tool calibration has become the industry standard for measuring and recording the length of individual cutting tools on milling machines. This method of tool measurement not only produces numerical values that make sense to the operator, and can easily be verified with a pocket scale, but will also allow for tool lengths to be set offline using a presetter - and then the data can simply be entered into the tool setup for that particular tool…helping to reduce setup time at the machine.

Several months ago I posted an article that explained Absolute Tool Length in detail. Since, as I mentioned above, this method has become the industry standard for almost all machine tool builders, and since all of our current day Hurco machines are shipping with this method as the default setting, I thought it would be helpful to repost a link to the original article for those who would like to learn more about it.

Please follow the link provided to view the original article: CLICK HERE

To download an informational .PDF please CLICK HERE