We Took Five for 5-axis…will you?

Hurco recently partnered with Modern Machine Shop magazine for an educational online 5-axis webinar, called: “Take Five for 5-Axis”. It was very well received by everyone who attended, and the feedback afterward was outstanding. In this webinar, I try to present this information in a very simple way, and attempt to explain things in a manner that even those who have no history of 5-axis machining can understand it. After all, that was the intention…to educate and teach!

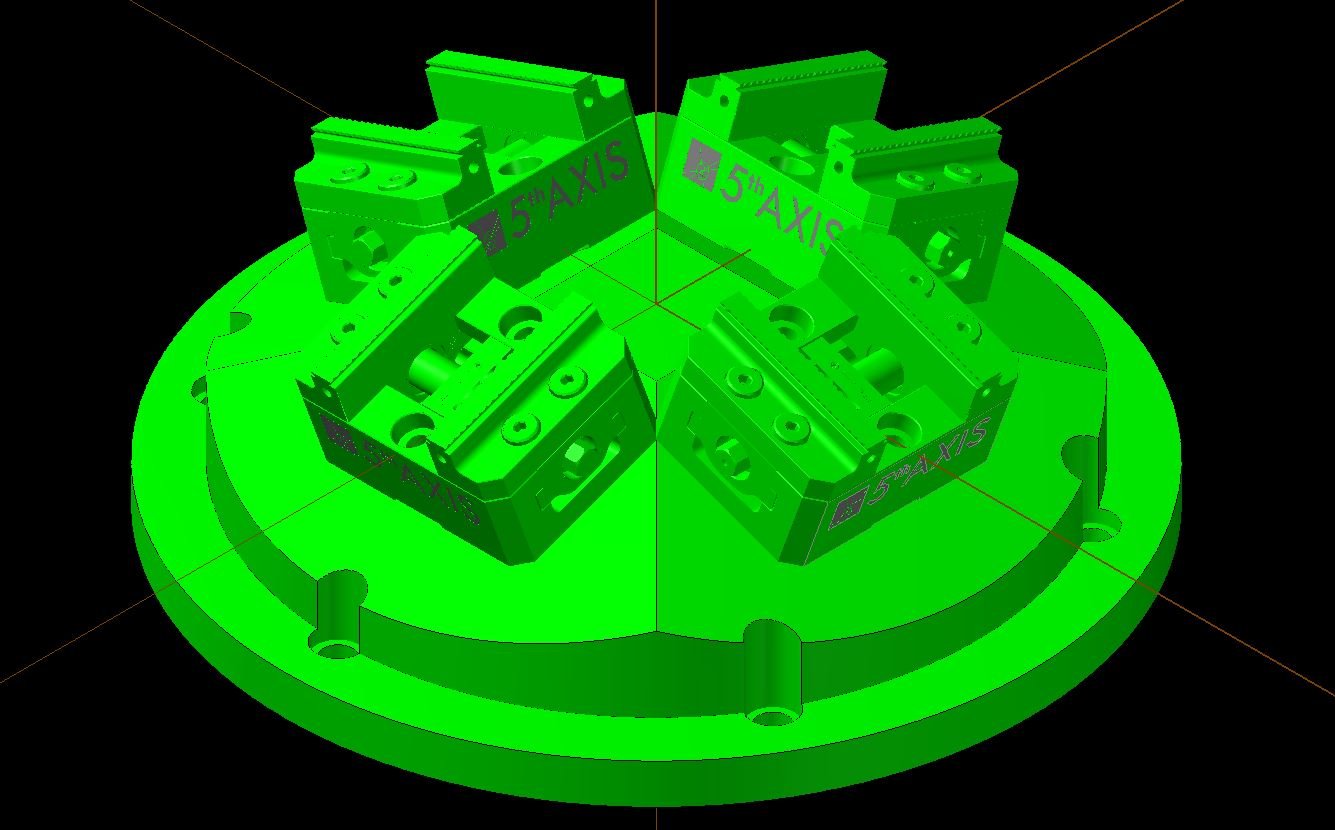

I begin with the basics of 5-axis as a foundation, and then build on that foundation as the presentation moves along. It starts off as elementary as discussing the common machine configurations and how to determine the correct nomenclature for the rotary and tilting axes, and then we move on to discuss things like workholding, the benefits of 5-axis vs. 5-sided or 3+2 machining, 5-axis terminology, and even cover some programming principles.

If you would like to learn more about the technology of 5-axis machining, then we hope you will click on this link to listen to the recorded webinar from Modern Machine Shop: www.hurco.com/take5

Here are some of the frequently asked questions that we receive about 5-axis machining. Maybe these will help you answer some of the questions that you may have:

- Do I need a CAM system for 5-axis programming? - the answer to this question is both YES and NO. If you are going to be running full 5-axis simultaneous type of work - such as impellers - then the answer is YES. However, if you are one of the 80% - 90% of the shops out there, who will only be programming 2D and 2.5D 3-axis work on multiple sides of the same part, then the answer is NO...and you can program those features using conversational programming.

- What kind of Return on Investment can I expect to see? - this is a hard question to answer, because every situation is different. Obviously the most dramatic difference will be in the improved efficiency of the setup process, but there will be improvements in actual cutting efficiency as well. We have noticed a pretty common 15% to 20% decrease in overall cycle times, due to the prioritized tool changes and position moves...as compared to running several separate programs. Here is a link to download an interactive ROI worksheet that will help you see what 5-axis can do for your shop: ROI Worksheet

- Are there any additional maintenance costs associated with 5-axis? - no, not really. All of the same maintenance items that apply to 3-axis machines, are the same as those that are necessary on a 5-axis machine. The only additional item that may be necessary - especially if you need to hold tight tolerances on your parts - is to periodically re-measure the centerlines for the tilting and rotating axes. These centerlines will be measured when the machine is installed, but, just like performing a Ball-Bar test on a 3-axis machine, it might be something that you will want to have checked annually to maintain workpiece accuracies.

- What CAM software do I need for 5-axis programming? - almost any modern day CAM software will work for programming both 5-axis and 5-sided (3+2) parts. Although, just like machine tool controls, some are better than others, and many will have their own unique features that make the process easier. The real hurdle is to create a good post processor for whatever machine tool you are trying to program. Whatever system you consider, try talking to the shops who are using that software for their work, and see what they have to say about it.