How AI is Revolutionizing the CNC Machining Industry

The integration of artificial intelligence (AI) into the CNC machining industry is rapidly transforming the way manufacturers design, produce, and optimize their operations. AI-powered solutions are enhancing precision, reducing waste, improving efficiency, and driving innovation across the sector. In this article we will explore how AI is being utilized in CNC machining and what the future holds for this evolving technology.

process optimization

One of the most significant applications of AI in CNC machining is smart automation and process optimization. Traditional CNC machines rely on pre-programmed instructions and manual oversight, but AI enables them to self-optimize through real-time data analysis. Machine learning algorithms analyze historical and live data to optimize cutting speeds, feed rates, and tool paths, leading to more efficient machining with reduced cycle times. At Hurco, we are beginning to capture this data within the control for use in the future. We hope to apply this technology to help automate machining processes and make machining and conversational programming more efficient.

predictive maintenance

Preventative maintenance schedules used to help reduce downtime are very important, and AI-driven predictive maintenance is revolutionizing machine reliability. Instead of relying on scheduled maintenance or reactive repairs, AI monitors the condition of CNC machines through sensor data and performance analytics. By detecting wear and potential failures before they occur, manufacturers can schedule maintenance proactively, minimizing unexpected downtime and extending machine life. Obviously, it is much easier and less detrimental to plan for machine downtime in the manufacturing schedule instead of reacting to it when something happens, and the machine is completely down until repairs can be made.

Enhanced inspection systems

Quality assurance is crucial in CNC machining, and AI-powered inspection systems are enhancing accuracy. AI-driven vision systems use high-resolution cameras and machine learning algorithms to detect defects, inconsistencies, and deviations from specifications in real time. These automated inspection solutions provide faster and more precise quality control than human inspectors, ensuring higher consistency in production. Here at Hurco, we have a few of our customers who use this technology, and the speed at which these vision systems can evaluate data and react when something is out of spec is truly amazing.

Enhanced inspection is also enabling CNC machines to become more adaptable. Adaptive machining techniques leverage AI to adjust machining parameters dynamically based on real-time feedback from sensors. This capability allows machines to compensate for material variations, tool wear, and environmental factors, leading to improved precision and reduced material waste.

CAM assist tools

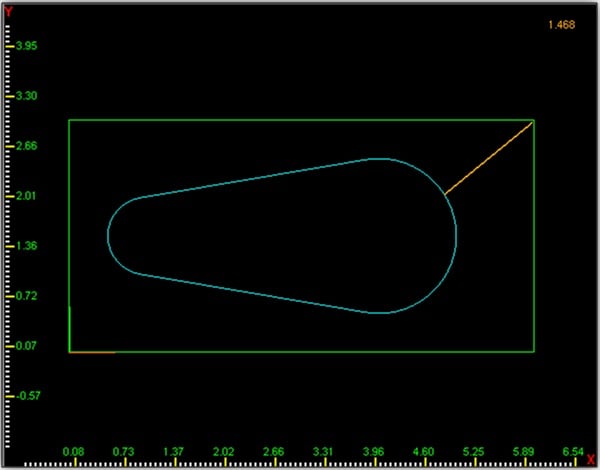

With the introduction of products like CAM-Assist by Cloud NC, AI is also transforming the way we program using CAD/CAM software. AI-driven CAD/CAM tools assist engineers in optimizing designs for manufacturability, suggesting the best machining strategies and automatically generating toolpaths. These AI enhancements reduce programming time, improve part quality and streamline production workflows. Notably, AI-powered CAM assist tools in software such as Mastercam and Fusion 360 are helping machinists by automating toolpath generation, optimizing cutting strategies, and providing real-time recommendations, making programming more efficient and intuitive.

supply chain and production planning

Effective supply chain and production planning are very important for any shop, especially smaller job-shops. AI is playing a crucial role in optimizing supply chains and production scheduling in CNC machining. AI-powered analytics help manufacturers predict material needs, minimize inventory costs, and streamline logistics. Additionally, AI-driven scheduling systems allocate machine resources efficiently, reducing bottlenecks and improving overall shop floor productivity.

future of CNC machining

The future of AI in CNC machining is exciting. As AI technology continues to evolve, we can expect even more advancements in CNC machining. The development of autonomous machining systems, where AI handles the entire production process with minimal human intervention, is on the horizon. Additionally, AI-powered digital twins — virtual replicas of CNC machines and manufacturing processes — will enable manufacturers to simulate and optimize operations before physical production begins.

AI is reshaping the CNC machining industry by enhancing automation, predictive maintenance, quality control, adaptive machining, and supply chain optimization. As AI continues to advance, manufacturers that embrace this technology will gain a competitive edge in efficiency, precision, and innovation. The future of CNC machining is undoubtedly being driven by AI, ushering in a new era of smart manufacturing.

You'll find more helpful resources, such as training videos and webinars, at Hurco.com/Connect.

Don't forget to subscribe to the CNC Machining Blog! You'll receive an email notification whenever a new post is published.