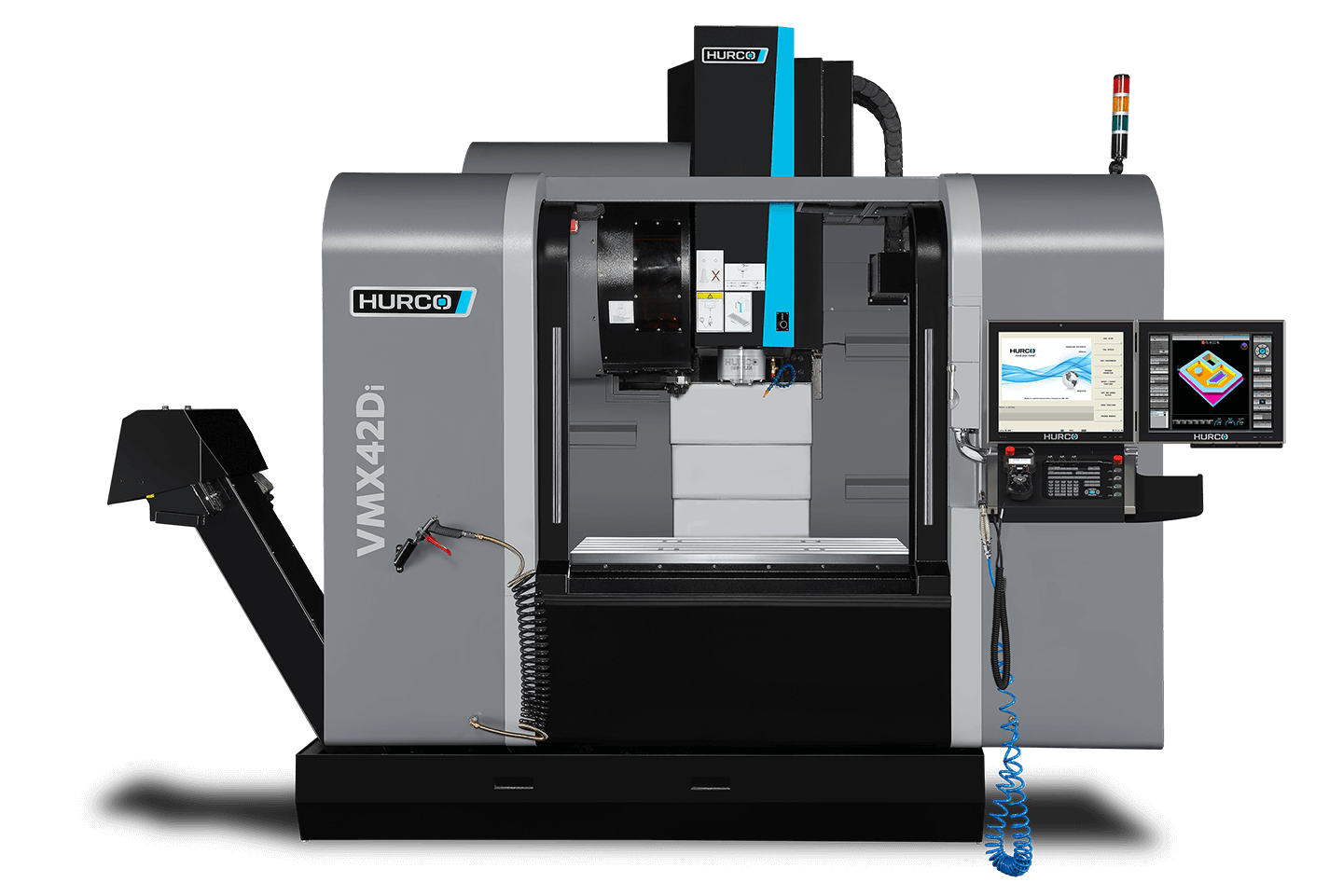

How It’s Made: Hurco VMX Series Iron

Hurco is known worldwide for our control software, and for conversational or “shop floor” programming, but we don’t often get enough credit for the machine’s iron. In addition to our award-winning control software, Hurco also builds a very robust and rigid machine tool that provides outstanding performance in any shop. That's why we decided to create the video below and write this blog post that highlights the design and manufacturing processes that we use at Hurco.

DOWNLOAD THE VMXi HOW IT'S MADE PDF HERE

THE CASTING

It all starts with the machine’s base casting. All Hurco castings are designed by Hurco engineers in Indianapolis, IN using FEA (Finite Element Analysis) to maximize efficiency and to simulate the real-world applications, stresses and pressures that the base casting and other cast components will endure throughout the life of the machine tool. FEA allows our engineers to analyze strength, vibration, and predict areas where thermal growth could be an issue. Therefore, the feedback FEA provides is used during the design process to make sure Hurco CNC machines are rigid and robust.

HAND SCRAPING

We hand scrape the casting mating surfaces to ensure that we have the most amount of contact area possible to promote increased rigidity and stability between those surfaces. Hand scraping also helps with surface flatness and assembly accuracy, which translates to better machine geometries and better part accuracy and surface finishes. This attention to detail, coupled with the quality components used in the building process, makes sure Hurco customers have a rigid, robust, and accurate machine that they can rely on for many years.

COMPONENTS & ASSEMBLY PROCESSES

How the axes are driven, and the components that they ride upon, are both very instrumental pieces to the quality and performance puzzle. From the way the heavy-duty ballscrews are pre-tensioned, to the use of roller linear ways instead of traditional ball linear ways for increased rigidity, Hurco designs a machine that will last.

LINEAR AXES

All three linear axes of the VMX series of machines ride on roller linear ways and are driven by direct-coupled axis motors that attach directly to the end of the ballscrew with no belts or pulleys. In addition to providing a faster response in direction changes the way the axis motors are attached ensures better accuracy over time – because there won’t be any lost motion that can occur as belts begin to stretch as they age. The roller ways are mounted and located against a machined and ground shoulder, fastened down with Socket Head Cap Screws, and tension is applied to keep the rail pushed against the shoulder with closely spaced wedges. All of this helps provide an extremely rigid and accurate system for mounting the roller ways.

BALLSCREWS

Pretensioned, double-nut ballscrews help drive the axes, and the double-nut ball assembly helps to reduce mechanical backlash. Because tension is being applied in two opposing directions – due to the precision ground shim in between the two pieces of the ball-nut - this keeps the steel balls that ride inside the ball-nut pushing against both the leading and trailing edges of the grooves of the ballscrew as the axes move.

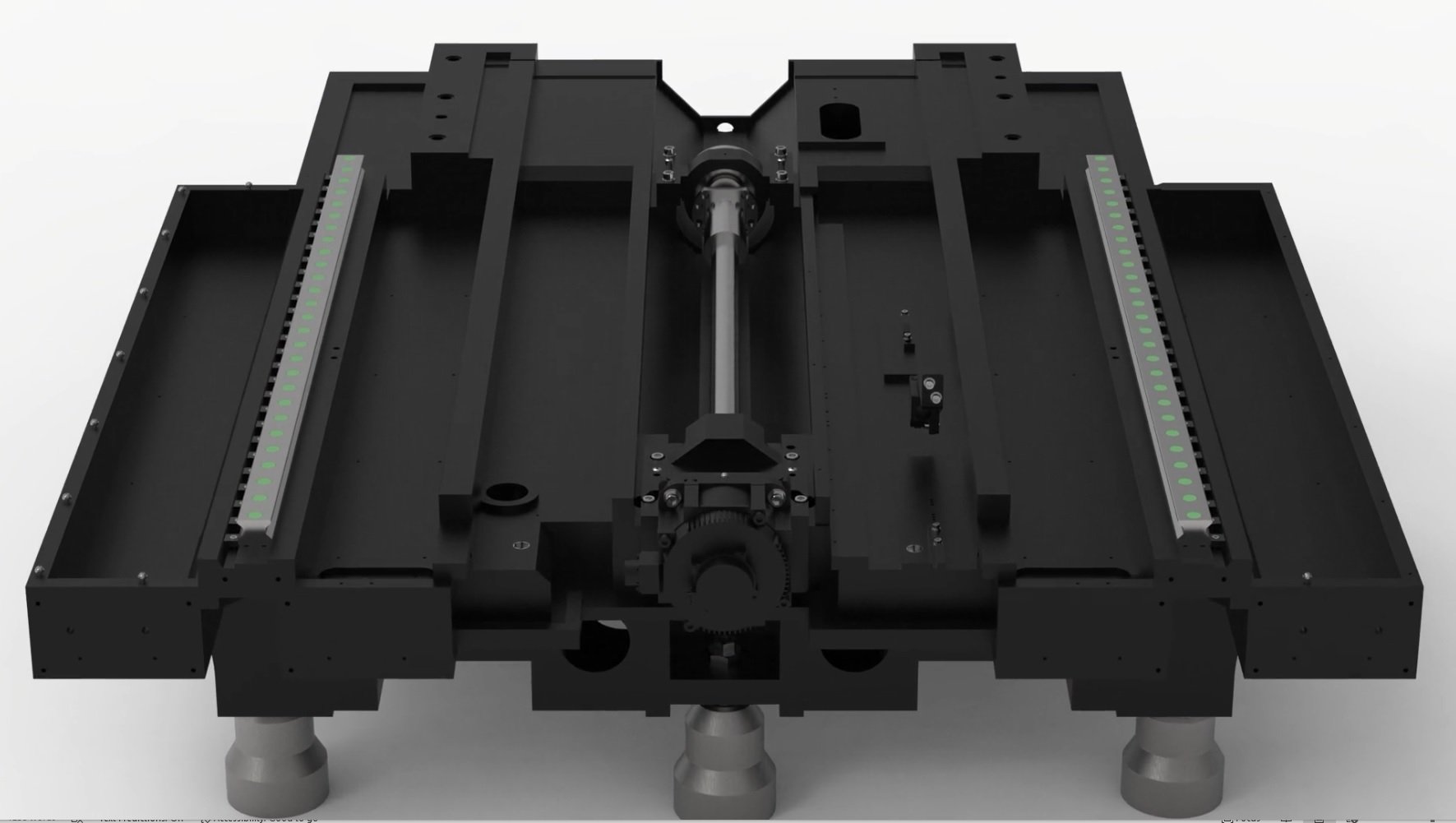

Y-AXIS LINEAR RAIL SPACING

Just like an athlete competing in a contact sport, who keeps their feet spread farther apart to give them a more stable platform, Hurco spaces the Y-axis linear rails farther apart to provide that same type of stable and rigid platform on which all other axis and table components are assembled. This offers the best protection against unwanted deflection and will help enhance overall rigidity and performance of the machine.

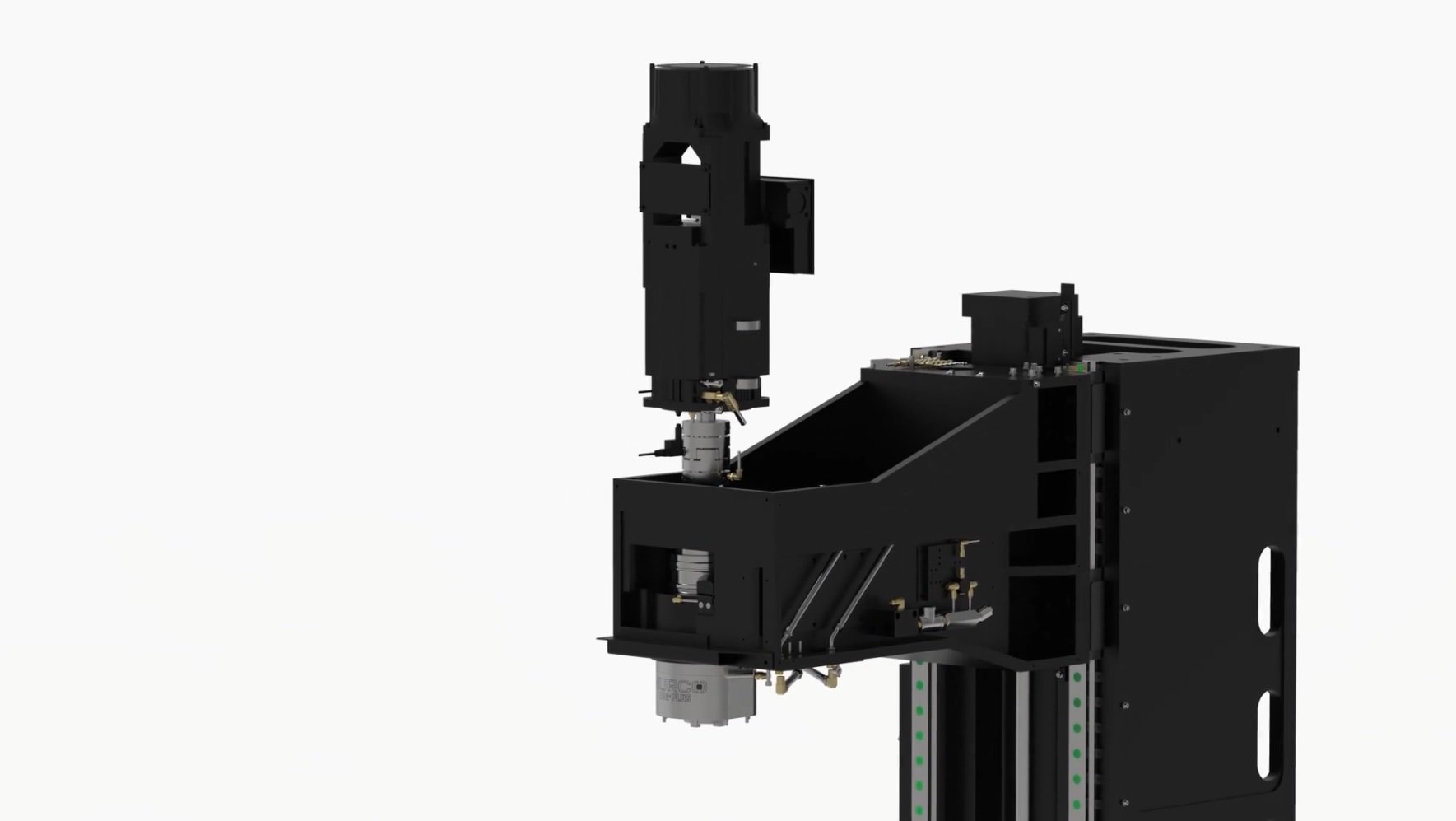

BIG PLUS® SPINDLES

Hurco spindles are equipped standard with BIG-Plus® dual contact capabilities. The BIG-Plus spindle configuration not only allows for contact on the inside taper of the spindle, but also provides contact on the face of the spindle nose. This dual contact design provides a very stable combination and is very useful when making very deep cuts while hogging lots of material and also when you’re using longer tooling that can deflect while cutting with a traditional configuration since only the inside taper is contacting the tool holder. Although Hurco spindles are BIG-Plus® compatible, traditional tooling can still be used on the machine. BIG-Plus® tooling is not required.

SPINDLE TYPE: Belt Drive vs. Direct Drive

The drive method for the spindles on Hurco VMXi machines can be either the traditional belt-driven design, or the newer direct-drive configuration. The belt-driven spindle utilizes a belt and pulley system to power the spindle. Due to the mechanical advantage of the design, the belt-driven spindles provide the extra low RPM torque that is sometimes needed for heavy machining with larger diameter tooling.

The direct drive spindle provides a much quicker acceleration and deceleration response, as well as a higher maximum RPM. With the direct drive spindle, the spindle motor is coupled directly to the top of the spindle itself, and there aren’t any belts or pulleys powering the spindle. There is also less heat build-up with the direct drive system, which will help prevent spindle growth during the machining process. VMXi machine spindles are equipped with ceramic-hybrid spindle bearings that help dissipate heat and diminish the amount of spindle growth. Both heat build-up and spindle growth can negatively impact part accuracy and surface finish.

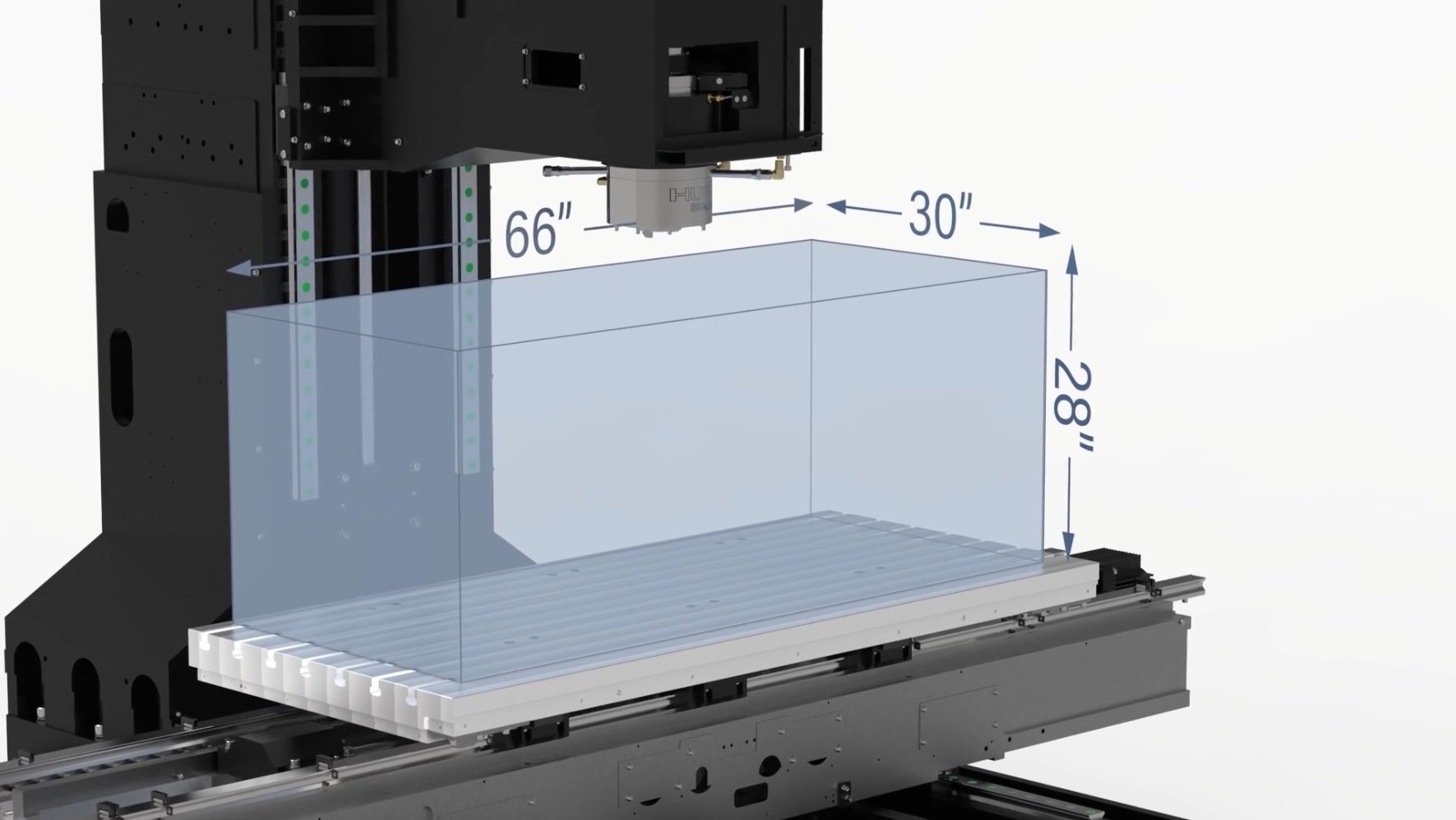

MACHINE TABLES

All machine tables on the Hurco Vertical Machining Center line-up are wider than the X-axis travel of the machine. The wider tables allow you to place fixtures, rotary table bodies, and other ancillary devices outside of the actual travel envelope of the machine tool, which lets you use the full X-axis travel of the machine tool when machining parts. The extra width will help accommodate a subplate as well. Since the subplate can extend beyond the machining envelope of the machine, there is more than ample support for any parts, vises, or fixtures that are placed on the subplate.

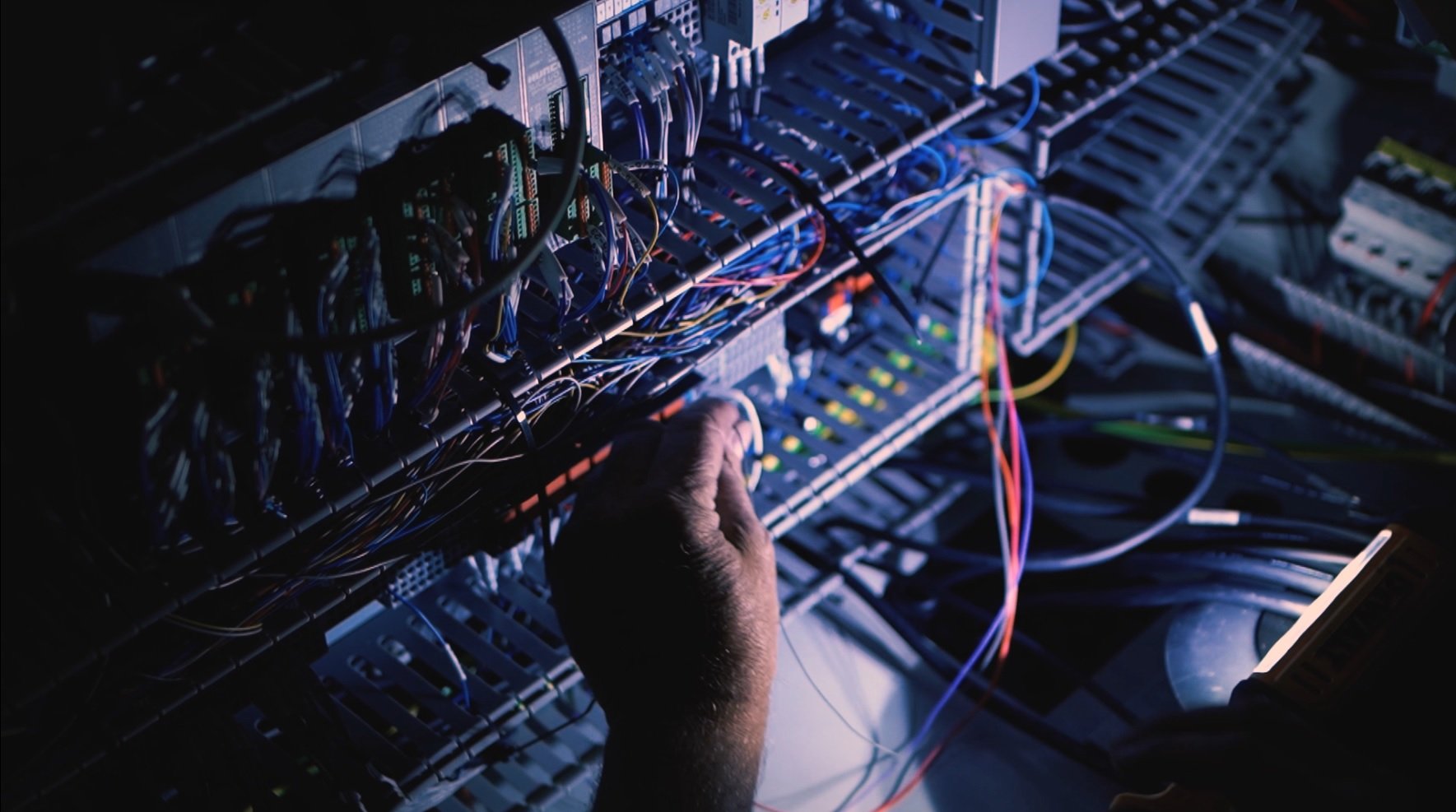

ELECTRICAL COMPONENTS

Although they don’t really fall into the category of machine iron, the type of electrical components that are used in a machine tool are also very important to the overall performance of the machine. Hurco uses all Yaskawa motors and drives in our machines. Yaskawa is a very well-known and respected brand that is both reliable and efficient. However, no matter how reliable a piece of electronics is, it will most likely need to be serviced at some point in its lifetime. Therefore, the labeling of the individual electrical components and overall layout of the electrical cabinet are critical to fast and efficient service. Hurco works very hard to make sure our electrical cabinets are laid out to provide the easiest serviceability possible. All components are labeled, spaced out for ease of access, and mounted on DIN rails for quick and easy removal or replacement. The control’s main brain is housed in one replaceable unit called the ITX module. Being able to remove and replace the ITX module very quickly allows the customer to have their machine back up and running very quickly while the suspect ITX module is sent back to Hurco service for repair.

SUMMARY

While Hurco is known for the most flexible CNC control in the industry that provides shops with multiple programming methods to get from print to part, we sometimes take for granted how the “iron” is designed and manufactured to withstand the rigors of metal cutting. We hope this video animation of the Hurco VMXi Series of Performance Machining Centers highlights the care, attention, and pride we take to make sure a Hurco CNC machine is built to make chips for decades. We could cut corners and cut costs, but our customers don’t want a throw-away CNC machine—they’re in it for the long haul…and so are we!

You'll find more helpful resources, such as training videos and webinars, at Hurco Connect.

Don't forget to subscribe to the CNC Machining Blog! You'll receive an email notification whenever a new post is published.