Why the Y?: Benefits of a Y-Axis on a CNC Lathe

In the world of CNC machining, efficiency and precision are critical. Traditional CNC lathes operate primarily on two axes: X (diameter) and Z (length). However, the addition of a Y-axis can make a huge difference in machining capabilities, enabling greater flexibility, efficiency, and cost savings.

One of the primary advantages of a Y-axis is the ability for off-center machining. The ability to machine features that are not aligned with the centerline of the part can be essential for operations such as milling, drilling, and tapping keyways or flats, which would otherwise require an additional setup on a milling machine. Although most features on the end of a workpiece can be performed by combining movements of the X & C axes simultaneously, work along the outside of the part often will need the Y-axis to perform the “off-center” operations.

The ability to move the turret above and below the centerline of the spindle will also provide the ability to utilize gang or multi-tool holders, therefore providing the ability to essentially double the number of available tools when programming. The ability to teach a tool offset for two different tools that are mounted to the same turret station can really help when machining workpieces with lots of features, because lots of features often equals the need for lots of tools.

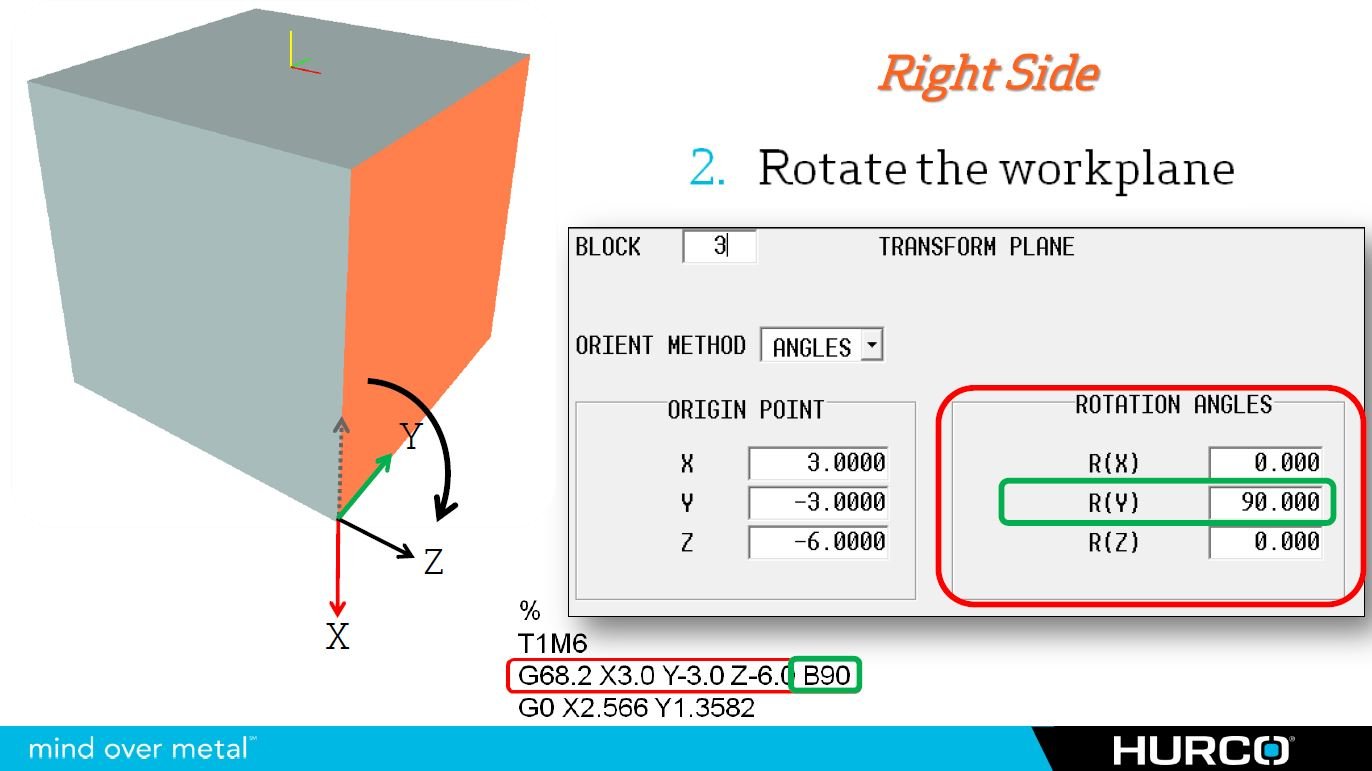

With the addition of a Y-axis, CNC lathes can execute true 3-axis milling operations. This enables features like pockets, slots, and intricate contours – even those with straight walls – to be machined on the lathe in one operation, basically eliminating the need for secondary machining processes on a milling machine as a separate setup.

By integrating the Y-axis into a CNC lathe, shops can complete multi-process operations in a single setup. The elimination of multiple setups on multiple machines reduces part handling time and overall production costs while also improving accuracy by minimizing potential alignment errors caused by excessive part handling and loading. All of this will help the shop become more efficient, and that can translate into a more competitive shop when it comes to quoting and winning contracts.

Adding a Y-axis to a CNC lathe opens a world of possibilities, from creating complex geometries more efficiently, to drastically reducing machining time and production costs. Whether you're producing intricate aerospace components, precision medical parts, or simple manifolds, a Y-axis-equipped lathe can take your machining capabilities to the next level. Investing in this technology not only enhances efficiency but also ensures that your shop stays competitive in the ever-evolving manufacturing industry.

You'll find more helpful resources, such as training videos and webinars, at Hurco.com/Connect.

Don't forget to subscribe to the CNC Machining Blog! You'll receive an email notification whenever a new post is published.