Is High-Speed Machining Right For My Shop?

When we hear the term high-speed machining (HSM), most people associate it with mold making. What people fail to realize is that this technology is being used effectively by shops of every kind to positively impact the bottom line — and isn't that what everyone wants?

When we hear the term high-speed machining (HSM), most people associate it with mold making. What people fail to realize is that this technology is being used effectively by shops of every kind to positively impact the bottom line — and isn't that what everyone wants?

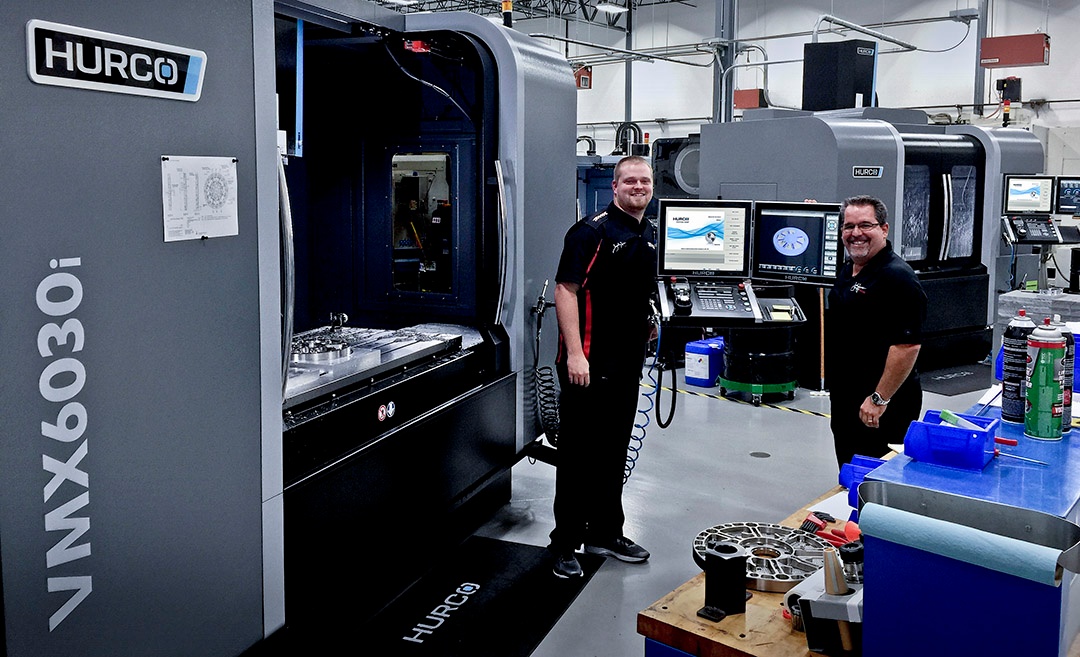

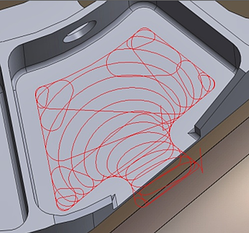

Although it's true that the die/mold industry was the first to incorporate HSM technology and to put it to good use, if you think about what HSM really is, you can easily begin to see opportunities in almost every type of manufacturing. Basically, anyone who needs to remove large amounts of material quickly should consider how HSM can help them become more productive. Who doesn't fall into that category?

Depending on the complexity of your work, you can expect to see an increase in productivity somewhere between 40% and 70%, especially if you are doing a lot of pocketing. Today’s CAM packages are using HSM algorithms to produce toolpaths that will help you get the most out of both your machine tool and cutting tools.

To see what HSM could mean for your shop, click on the link below to download our interactive HSM return on investment worksheet. Simply plug in the numbers that make sense for your particular application, and the worksheet will show you the results!

If you want to learn more about HSM in general, you can read a previous blogpost of mine for more information: http://blog.hurco.com/blog/bid/214906/High-Speed-Machining-it-s-more-than-just-a-faster-spindle.