5-Axis Machine Purchasing Considerations: Size Does Matter

There are several things to keep in mind when you are in the market for a new 5-axis machining center. To be successful, you must make sure that the machine will fit all of your needs, not just your current one. Often times the purchase of a 5-axis machine is driven by a particular job or part, and sometimes shops fail to consider the other work they could run on the machine. Remember, size does matter.

Although size is a factor on all 5-axis machine configurations, the trunnion machines seem to be the ones that catch people off guard most often. A trunnion-style machine must be specifically sized for the family of parts that will be run on the machine. If not, there will be unexpected beartraps to get caught in. When buying a 3-axis machine, we have always been taught to buy the biggest machine that you can afford, providing for the ability to run larger work in the future. This logic doesn’t work with a trunnion 5-axis machine.

If you are running small-to-medium-size parts – 3” to 6” cubes – then you don’t want to buy a large machine with a 24” diameter rotary table. Running small parts on a large trunnion means you will need to use extended-length tooling to reach the center of the table when the trunnion is tilted to 90 degrees. This can cause all kinds of problems like chatter, slower feed rates, interference issues, inability to toolchange such long tools, etc. If the machine you purchase is a medium-size machine – 10” or 12” diameter table for example – then standard-length tooling can be used, and many of the issues mentioned above will not become a problem – at least not because of a machine that is too large.

Another factor in choosing the correct trunnion machine is part height. Although many of the smaller footprint 5-axis trunnion machines have more than adequate Z-axis travels and clearances for medium to large workpieces, it is the Y-axis travel that must be considered. For example: if you mount a part on the table of a smaller machine, and the height of the part and fixture combined reach a height of 10”, you will most likely get an out of travel alarm when you try to run your program. This is because the machine will not have enough Y-axis travel to reach the top of the part when the trunnion is tilted to 90 degrees.

The Y-axis travel issue is the single most overlooked consideration when purchasing a trunnion style machine and is usually compounded by the overwhelming selection of modular-style, 5-axis fixtures available. Once you mount the system’s baseplate and add the modular pallet that will hold the centering vise, you have already used up the machine’s entire available work envelope, and you haven’t even clamped the part in the fixture yet!

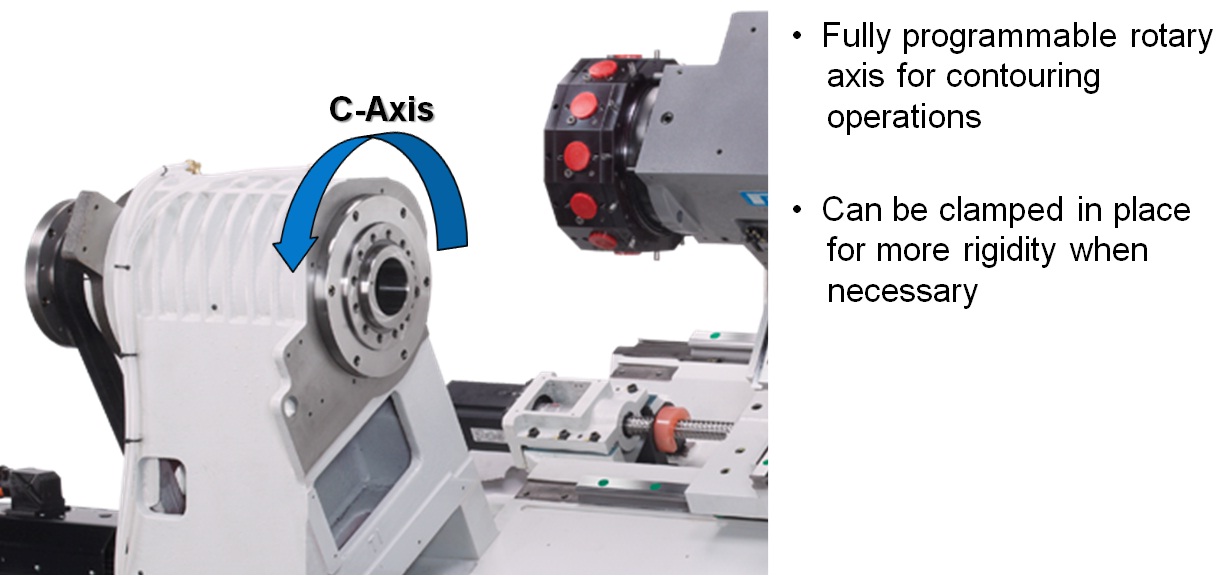

The issue with swivel-head machine configurations is similar but has an X-axis travel limitation. As the head tilts from one side to the other, the X-axis has to also move to accommodate the tool length, and the longer the tool and bigger the part, the larger the machine will need to be.

As you can see in the image above, the X-axis will need to move to the right to allow clearance for the tool to position on the left side of the workpiece, and as I said, the longer the tool or bigger the part, the farther the axis will need to travel. Therefore, for larger parts – especially when deep-hole-type operations are necessary – you should be considering a machine with as much X-axis travel as possible.

Is 5-axis the right choice for you and your shop? Download the 5-Axis Return on Investment worksheet below to find out!