Is Conversational Programming Dead in Modern Machining?

During my 35+ years in manufacturing, I have worked at several shops and visited hundreds more. In the vast majority of these job shops, there has been at least one CNC machine with some type of conversational programming; in many of these shops, they used conversational programming for most of their work.

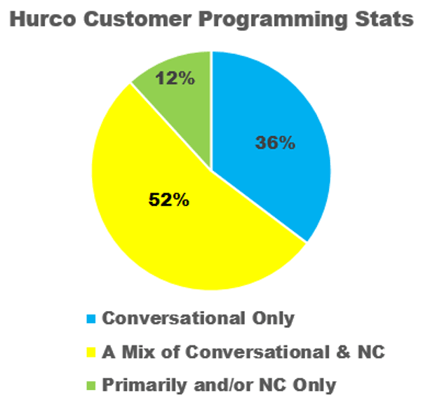

However, in the last 15 years, there have been rumblings that the use of conversational programming is on the decline, and therefore conversational is no longer a viable option for programming parts on a CNC machine. Keep reading to see why I disagree with this premise. But first, let me give you some stats from our customer surveys:

When you combine the yellow and blue portions of the pie chart below, you’ll notice that 88% of our customers still find conversational programming helpful, useful, and a relevant way to produce parts - even in today’s supposed “CAD/CAM only” manufacturing environment.

I firmly believe that conversational programming is as useful today as it was back in the day. Once we take a closer look at the changes that have occurred during the last 15 years, I think you will see that a change in how shops receive their jobs is what has led to the misperception that conversational is dead.

Machine Shops: Then vs Now

In the past, shops received electronic drawing files in either DXF or DWG file formats, or they would be provided with a paper blueprint from their customers. Since the majority of job shop work is 2D or 2.5D, with what could be described as simple machined features (milled edges, drilled holes, simple pockets or profiles), it was easy to sell the idea of a CNC machine with a conversational control that could be quickly programmed on the shop floor by the operator.

However, as CAD/CAM software has become more prevalent, more engineering companies have started to use this type of software for designing parts. Therefore, shops started receiving more solid models from their customers instead of blueprints and/or DXF or DWG files. Creating paper copies of blueprints from these files and extracting the necessary data from the solid model files to use for conversational programming instead of NC is often just too time consuming.

Although the types of parts haven’t necessarily changed, these additional steps in the process simply defeat the overall benefit of speed and ease that conversational programming offered shops in the past, and I believe that is the real reason for the swing toward CAM systems and NC programming.

So, this must mean that conversational programming is dead, right?

Absolutely not!

Conversational key for high-mix, low volume

Conversational programming provides the flexibility you need to bring order to the chaos of high-mix, low volume manufacturing. In addition to the basic ease and speed of programming, conversational programming offers another key benefit that CAM programming doesn’t: flexibility.

The flexibility of conversational gives you the power to tweak or make changes to the program on the fly (change part feature dimensions, change tooling sizes, alter peck depths, etc.), at the control, and without the need to make changes to the CAM file and repost the program from a computer located in an office somewhere. This flexibility can be a huge time saver for high-mix, low volume shops where throughput is so important.

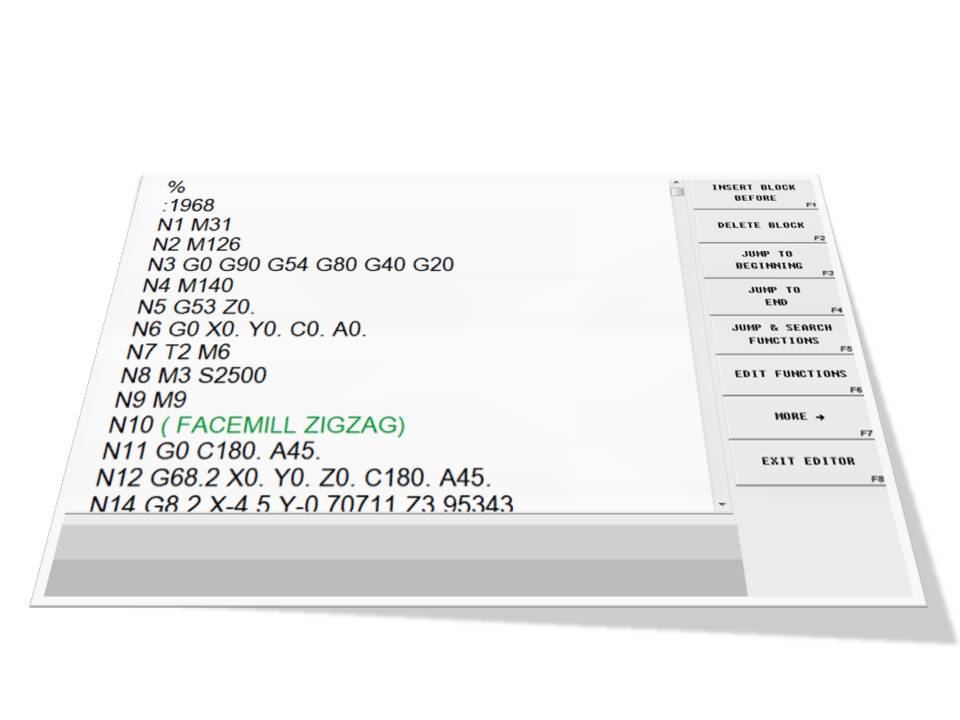

One feature in particular that takes flexibility to a whole new level is Hurco’s NC/Conversational Merge. NC/Conversational Merge is a tremendous advantage because it lets you merge NC programs with conversational programs and allows the use of features such as transform plane and pattern data blocks. The ability to merge G-code programs with these pattern blocks allows you to incorporate 3-axis subprograms in a linear or grid pattern, rotate or scale the G-code programs, mirror image them, or even insert them in a conversational transform plane data block on a 5-axis machine for multi-sided machining — all without ever changing any of the G-code itself. It also allows the operator to program simple geometry at the control and then merge in the G-code for features such as 3D surfacing where the use of a CAM system was necessary.

Time and again, shops that say they won’t ever use conversational change their minds once they see just how powerful features like NC/Conversational Merge are, or how fast and easy conversational programming is in general for things like stock preparation or fixture machining.

Video link to:

- NC Merge with Patterns

- 5-Sided Conversational Programming Demonstration

- 3-Axis Conversational Programming Demonstration

Evolution of the Conversational Control

Hurco invented conversational programming, therefore our purpose has always been to make job shops more productive (and profitable) by delivering CNC machines equipped with sophisticated control technology that provides flexibility and reduces setup time. That’s why we continue to strengthen and adapt our control’s ability to adapt to industry changes and the needs of its users.

The most significant feature we’ve added to conversational programming addresses the changes we’ve seen in the industry during the last 15 years that I mentioned previously. The feature is called 3D Import, which has two components to it: Solid Model Import and 3D DXF.

Solid Model Import allows the operator to import a solid model file directly into the CNC control and to create conversational data blocks by selecting feature geometry on that model. This offers the user a powerful feature that will allow shops who love conversational a way to bring it back for their CNC machinists. It also provides – as does conversational programming in general – a way to help shops train new operators.

Video link to:

As shops find themselves knee-deep in the pains caused by the skills gap and labor shortage, conversational programming can help shops get a less skilled operator trained and programming parts much quicker than alternative CAD/CAM methods. It also eliminates the need for them to learn G-code programming before they can contribute significantly to the manufacturing process, thereby eliminating a potential job flow bottleneck in the machine shop caused by this new employee having to wait for someone else to program even the simplest of parts.

An operator at John Force Racing’s machine shop explained it best when he said, “I wasn’t a programmer by any stretch of the imagination before I ran Hurcos, but now that I am doing conversational, I’m a setup operator that can program."

We also see many of our new Hurco customers – again, who thought they would never use the conversational programming - quickly adopt conversational once they are exposed to all of its possibilities. One such customer was Virginia Tech College in Blacksburg, Virginia.

Virginia Tech already had some CNC machines, and they were programming them all via CAD/CAM software. After the install and initial training on the Hurco, there was still almost two full days of training left on the schedule. Even though the graduate students in this prototype lab were convinced there was no reason they would ever switch from CAD/CAM programming, they ultimately decided they might as well learn a little bit about the conversational control since someone was there.

Once they learned how easy and powerful Hurco conversational programming is, they immediately sidelined CAD/CAM programming for almost all of their projects and switched exclusively to conversational. In fact, their excitement for conversational sparked interest in another department at the university, which led to that department purchasing a new Hurco machine for their lab; they program in conversational almost exclusively as well.

verdict: conversational is alive and well

At the top of this blog post, I provided data about the use of conversational programming and NC programming that we gathered from our customers. I imagine if you’re a skeptic about the value of conversational programming, you might think, “Well, of course Hurco customers use conversational programming. Hurco is the inventor of conversational programming!”

What about non-Hurco people? Do they care about conversational programming?

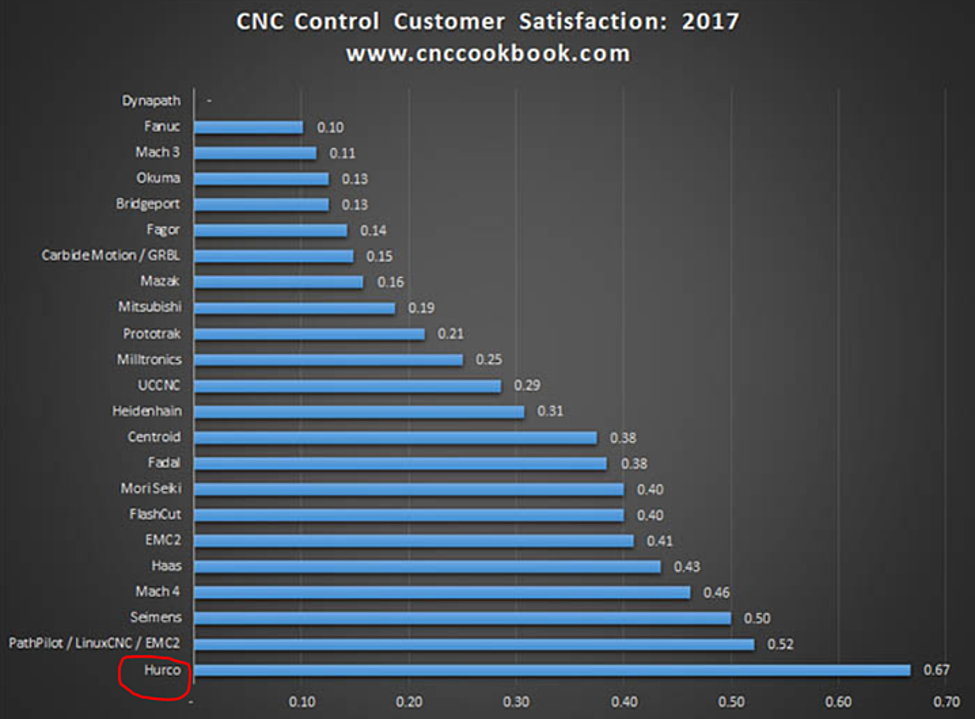

Interestingly, a company called CNC Cookbook did a survey on just that subject. The owner of this third-party website, not affiliated with Hurco whatsoever, told us the survey consisted of about 500 respondents who operate various brands of CNC machines. Even better, they told us Hurco ranked number one!

What is even more interesting to me about this survey is the fact that this was not a survey about conversational controls; controls such as FANUC and other basically “NC only” controls are on the list as well.

After all of the data we received from our own Hurco surveys, coupled with our own experiences in the industry with both new and existing Hurco customers, it is refreshing to see that what we believed all along is actually very true. As evidenced by the CNC Cookbook survey results, conversational is not only not dead, but it is actually thriving in the modern manufacturing environment.

As Bob Warfield from CNC Cookbook explains in the survey results, every CNC machine needs to focus on ease of use and, “Add a really good Conversational CNC. Folks, I don’t think it’s a coincidence that two of our Gold Customer Satisfaction winners, Hurco and PathPilot, are known for great Conversational CNC.

"Things happen on the Shop Floor. The round trip to make a change by updating or creating a CAD model, running it through CAM, and then coming all the way back to putting G-code on the machine is a long one. It’s fine for complex parts, but why am I running around that track when I just want to put a few holes in a rectangular bracket?

"Every CNC Control should have great Conversational CNC!”

You'll find more helpful resources, such as training videos and webinars, at Hurco Connect.

Don't forget to subscribe to the CNC Machining Blog! You'll receive an email notification whenever a new post is published.