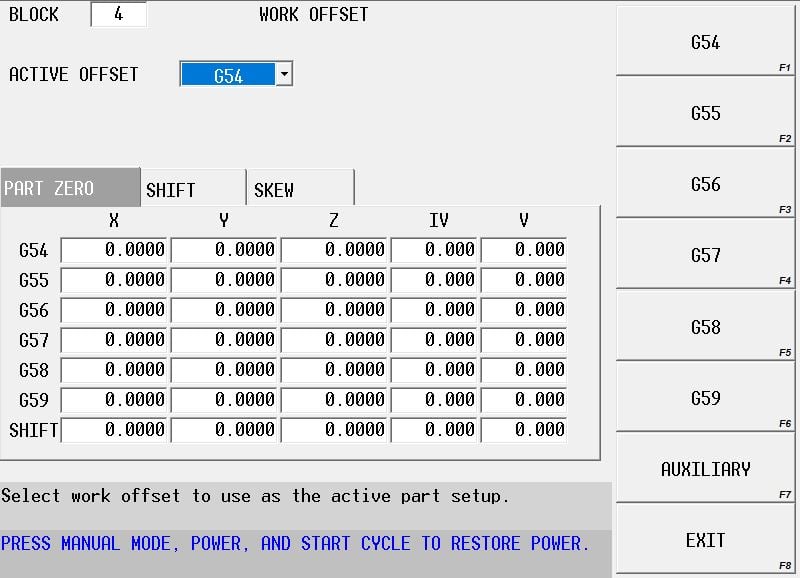

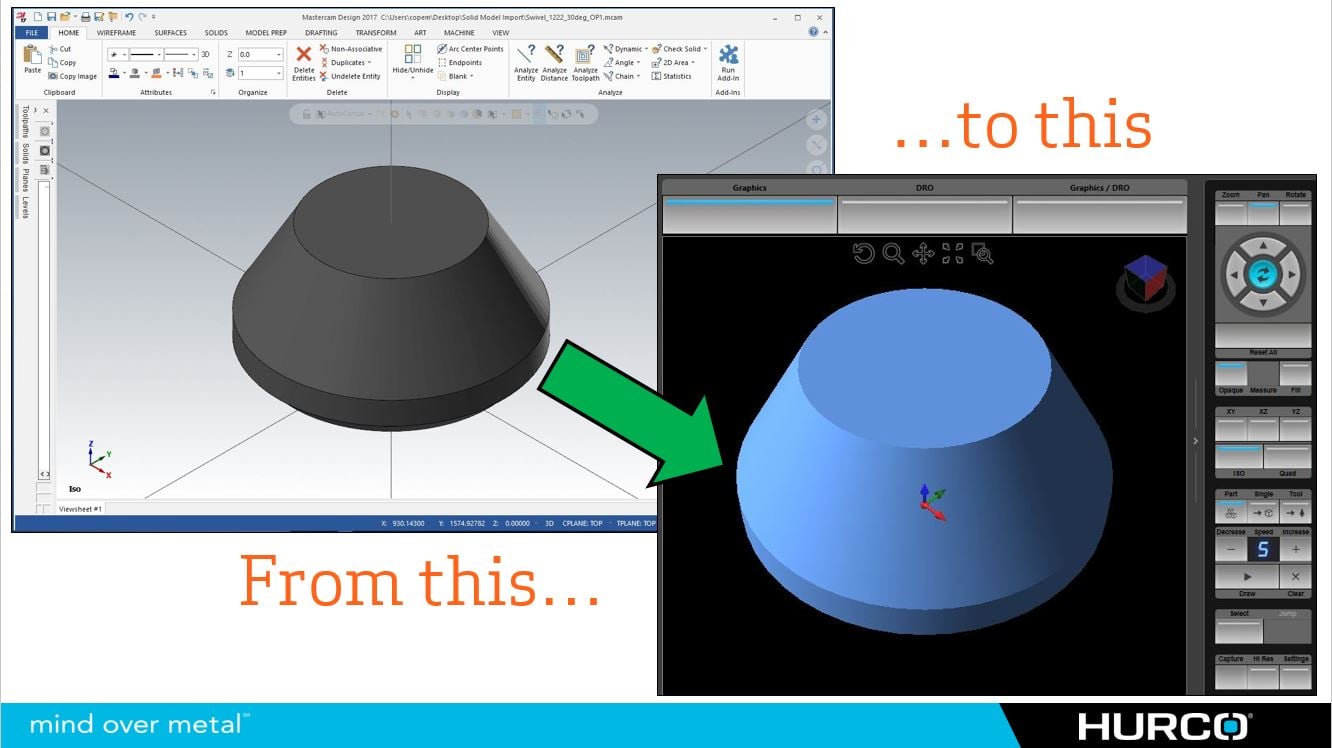

Importing Solid Model STL File as Stock Geometry in WinMax Software

The ability to import an STL file for stock geometry is a Hurco WinMax feature I'm excited to discuss. Although many people have this feature on their controls, they either aren't aware of it or don't know how to use it. I thought it was worth a quick blog post and video.