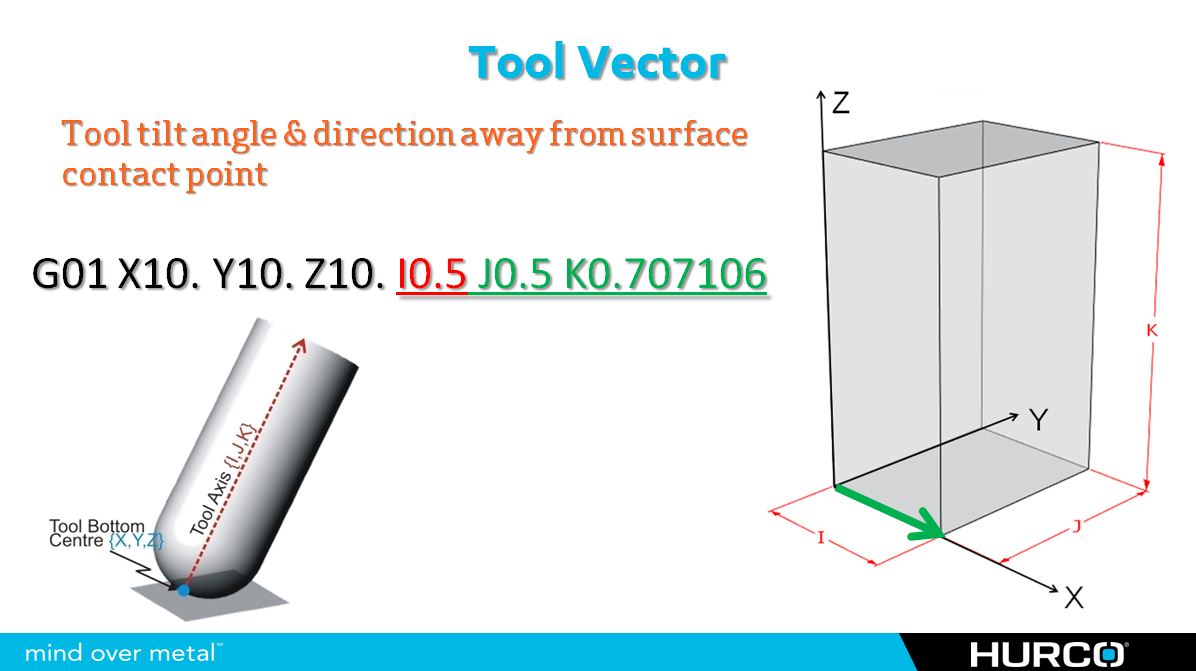

5-Axis CNC Programming: Rotary Angles or Tool Vectors?

When programming in 5-axis, we have two distinct options that we can use to command rotary moves and positions. We can output the data using either rotary angles or tool vectors. Although each one has its pros and cons, I prefer to configure a postprocessor to output these rotary commands as IJK tool vectors, instead of the more common ABC-axis rotary angles.