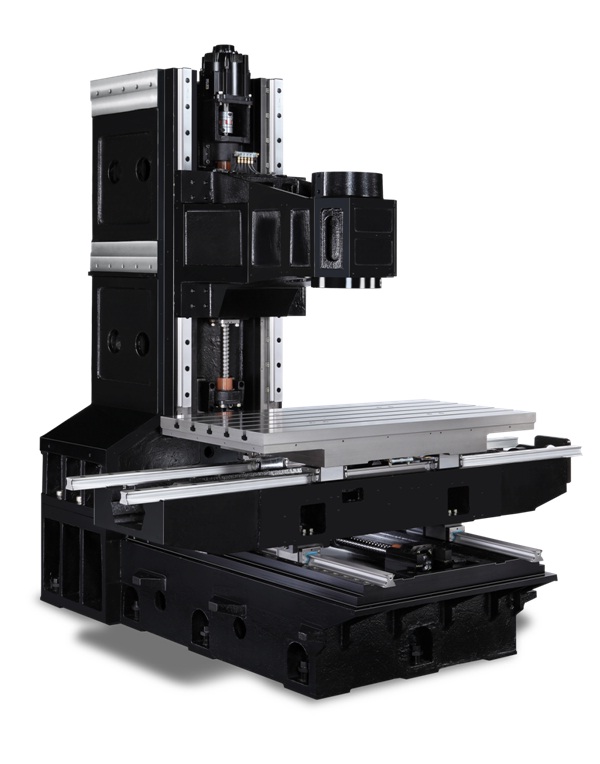

Hurco Machines – what’s beneath the kilt?

I recently received a request from a reader to talk about what is under the sheet metal on the Hurco machines, and to discuss the components that make them so rock solid. Having been a fan of Hurco machines for quite some time now, I am happy to oblige this request.