PUBLISHED: NOV. 7, 2014

UPDATED: AUG. 3, 2023

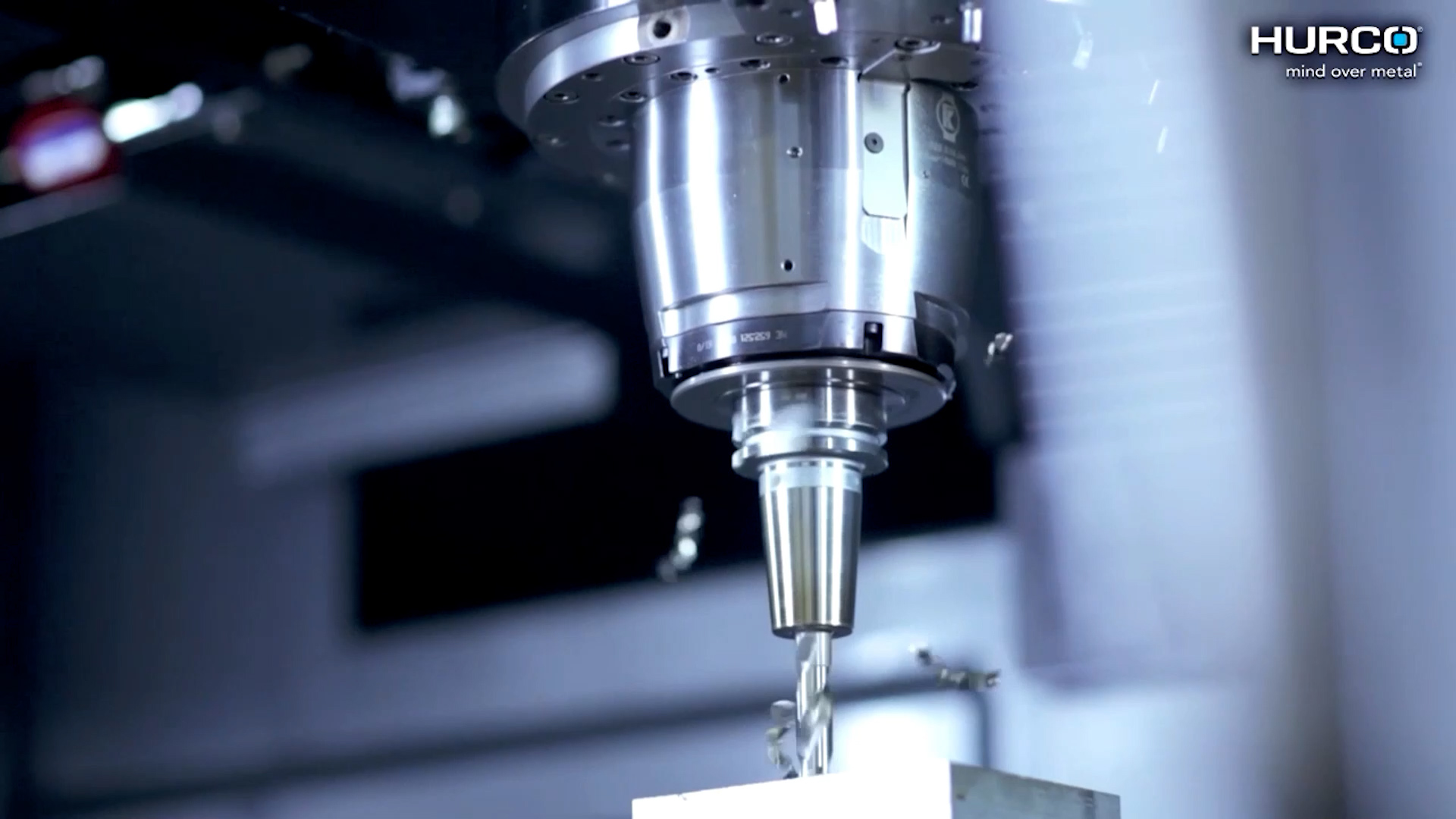

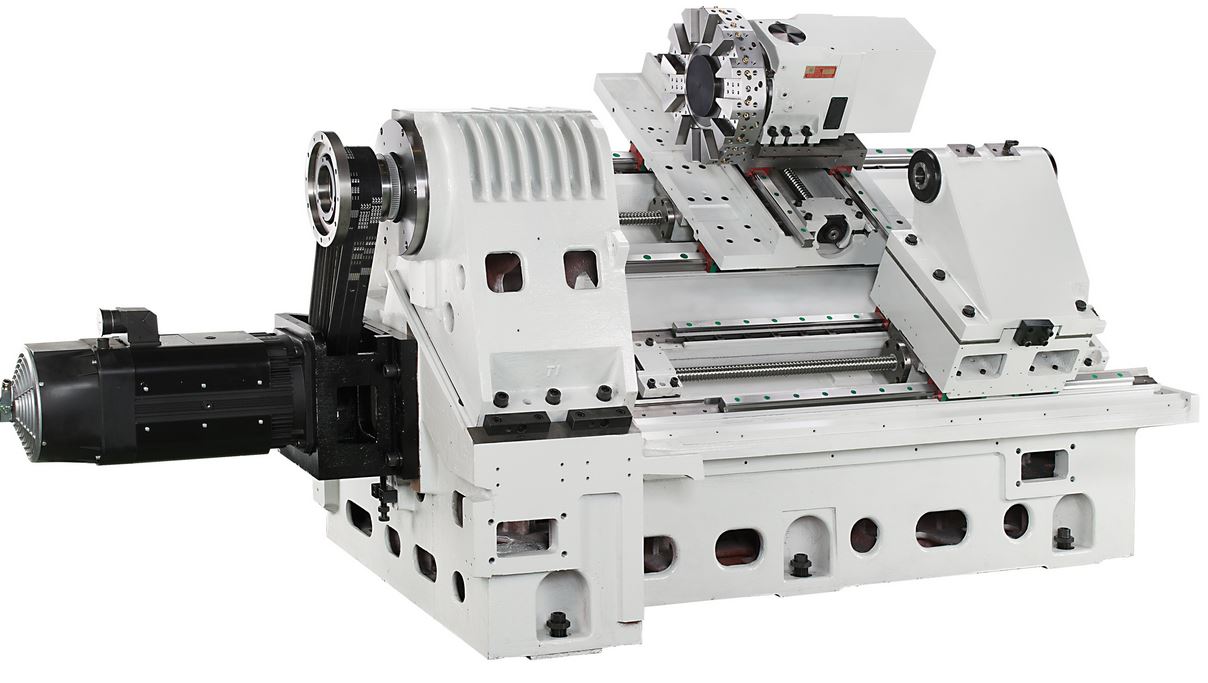

When people hear the term “automation,” it usually conjures visions of high-production processes, where shops are running hundreds of thousands of the same part. But in today’s ever-changing and increasingly competitive industry, that is not always the case. Just like many small job shops have begun to migrate toward 5-axis machines to increase multi-sided part efficiency, those same shops are also beginning to move toward automation to help them increase profits.

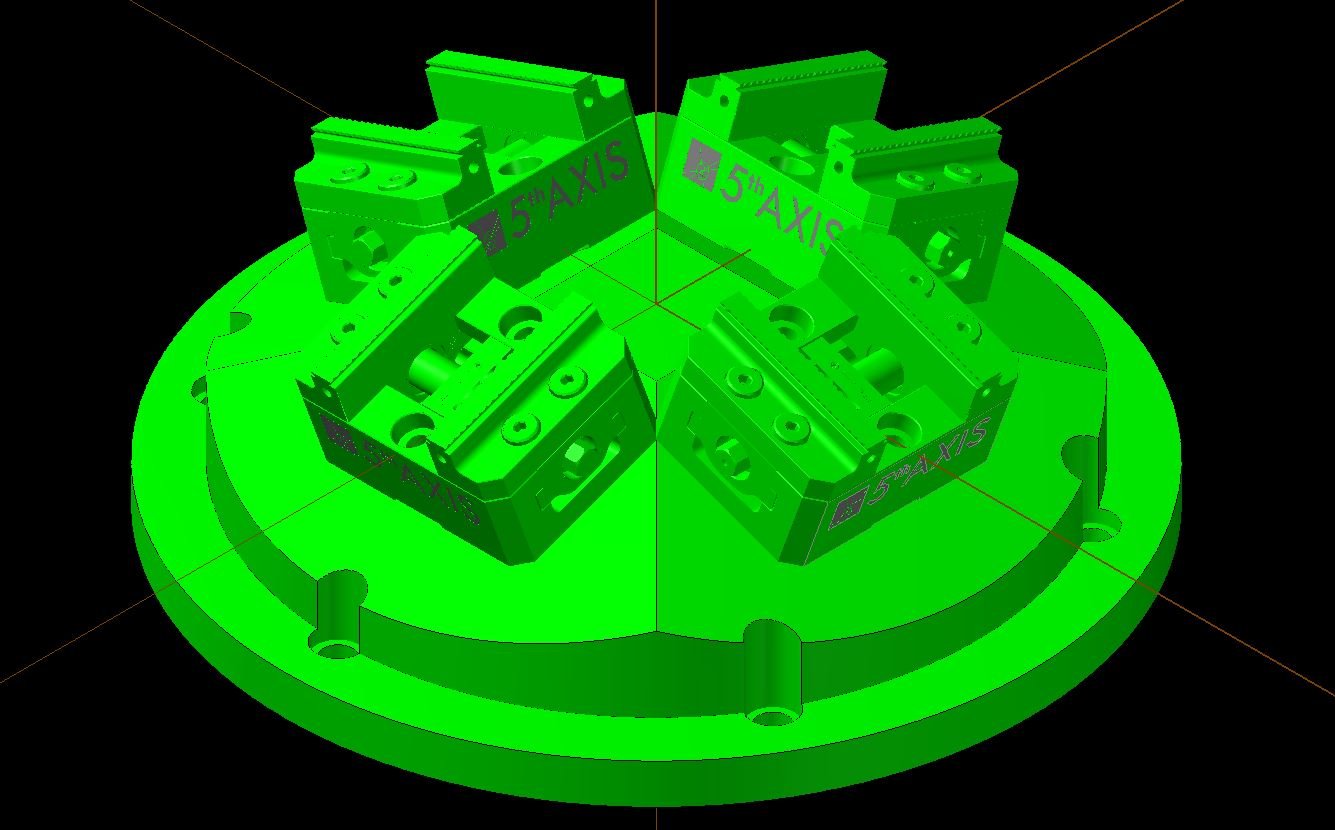

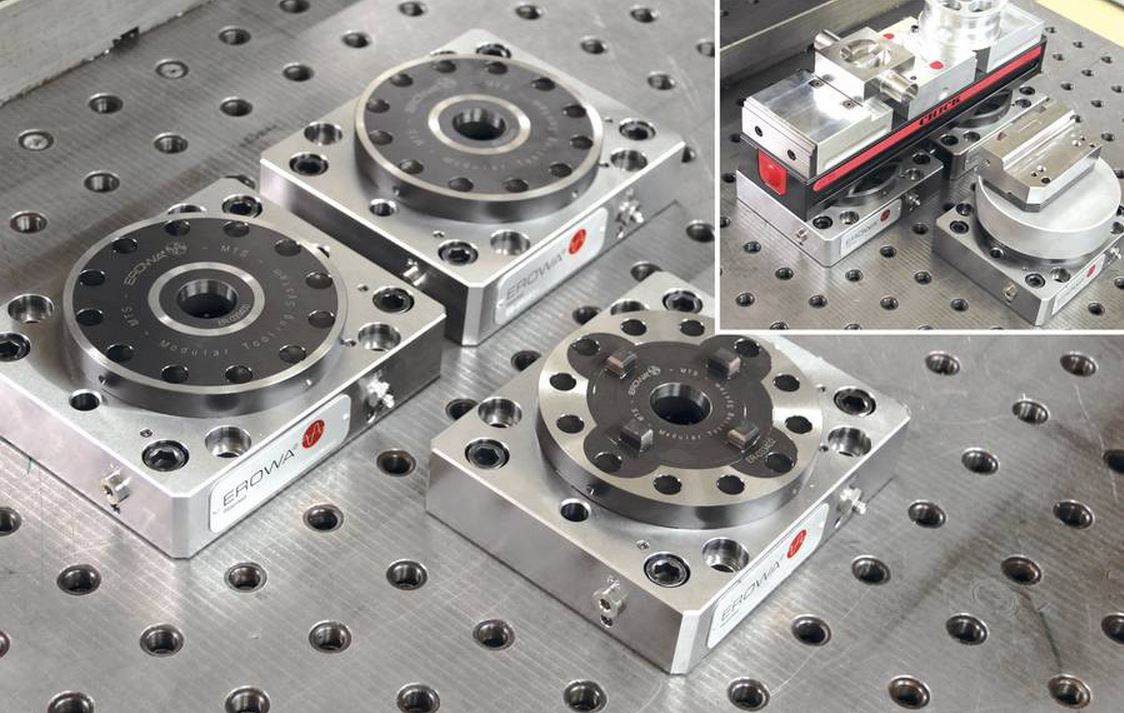

To understand and begin this migration toward automation, you first must understand and buy in to the ideas of standardization and palletization. Winning in the game of high-mix, low-volume part manufacturing means reducing spindle downtime. The first step towards winning that battle is standardizing your setup process. At the end of the day, you can only invoice for the parts that you have completed. So, reducing idle time between jobs is a crucial step to getting more done in a typical eight-hour shift.